Part V. Inspection Requirements for Trucks and Other Vehicles over 10,000 Pounds (Gvwr)

19VAC30-70-430. Inspection -- heavy vehicles.

A. Inspection procedure -- heavy vehicles:

| 1. Remove existing inspection sticker (all vehicles). 2. While in right front, inspect right side glass and right side lug nuts, windshield, seat belts, and door latches. 3. Drive vehicle into inspection lane. 4. While in driver's seat, check left side glass and window crank, windshield, driver's seat, seat belts, door latches and parking or holding brake. Check service brake, high beam indicator, turn signal switch, air brake low air warning, air pressure loss, (single/combination) horn, windshield wiper, defroster, mirrors, steering lash and floor pan. 5. Check exhaust system and fuel tank. 6. Check right side marker and clearance reflectors. 7. Check all rear lights (including brake and turn signal). Check all rear reflectors. |

| 8. Check left side marker, clearance lights and reflectors. 9. Check all wheels for brakes, push rod travel, tires, rims and suspension. 10. Check headlights, fog, driving, turn signals, other lights and reflectors. 11. Check steering system, ball joints/king pin, shocks, springs. 12. Open hood and check latching mechanism, master cylinder, engine mounts, and compressor belts. 13. Check frame (all vehicles) and coupling device. 14. Check air lines and couplings. Disconnect emergency air line (red) (left) and check for automatic operation of trailer breakaway brakes. Check tractor air protection valve. (Combination vehicle only). 15. Issue approval or rejection sticker. |

B. Inspection guidelines. Required lamps and reflectors on commercial vehicles.

Lamps and reflex reflectors. Table 1 specifies the requirements for lamps, reflective devices and associated equipment by the type of commercial motor vehicle. The diagrams in this section illustrate the position of the lamps, reflective devices and associated equipment specified in Table 1. All commercial motor vehicles manufactured on or after December 25, 1968, must, at a minimum, meet the applicable requirements.

| Table 1 | ||||||

| Item on the vehicle | Quantity | Color | Location | Position | Height above the road surface in millimeters (mm) (with English units in parenthesis) measured from the center of the lamp at curb weight | Vehicles for which the devices are required |

| Headlamps | 2 | White | Front | On the front at the same height, with an equal number at each side of the vertical center line as far apart as practicable. | Not less than 559 mm (22 inches) nor more than 1,372 mm (54 inches) | A, B, C |

| Turn signal (front)2, 12 | 2 | Amber | At or near the front | One on each side of the vertical centerline at the same height and as far apart as practicable. | Not less than 381 mm (15 inches) nor more than 2,108 mm (83 inches.) | A, B, C |

| Identification lamps (front)1 | 3 | Amber | Front | As close as practicable to the top of the vehicle, at the same height, and as close as practicable to the vertical centerline of the vehicle (or the vertical centerline of the cab where different from the centerline of the vehicle) with lamp centers spaced not less than 152 mm (6 inches) or more than 305 mm (12 inches) apart. Alternatively, the front lamps may be located as close as practicable to the top of the cab. | All three on the same level as close as practicable to the top of the motor vehicle. | B, C |

| Tail lamps5, 11 | 2 | Red | Rear | One lamp on each side of the vertical centerline at the same height and as far apart as practicable. | Both on the same level between 381 mm (15 inches) and 1,829 mm (72 inches). | A, B, C, D, E, F, G, H |

| Stop lamps5, 13 | 2 | Red | Rear | One lamp on each side of the vertical centerline at the same height and as far apart as practicable. | Both on the same level between 381 mm (15 inches) and 1,829 mm (72 inches). | A, B, C, D, E, F, G |

| Clearance lamps8, 9, 10, 15, 17 | 2 | Amber | One on each side of the front of the vehicle | One on each side of the vertical centerline to indicate overall width. | Both on the same level as high as practicable. | B, C, D, G, H |

| 2 | Red | One on each side of the rear of the vehicle | One on each side of the vertical centerline to indicate overall width. | Both on the same level as high as practicable. | B, D, G, H | |

| Reflex reflector, intermediate (side) | 2 | Amber | One on each side | At or near the midpoint between the front and rear side marker lamps, if the length of the vehicle is more than 9,144 mm (30 feet). | Between 381 mm (15 inches) and 1,524 (60 inches). | A, B, D, F, G |

| Reflex reflector (rear)5, 6, 8 | 2 | Red | Rear | One on each side of the vertical centerline, as far apart as practicable and at the same height. | Both on the same level, between 381 mm (15 inches) and 1,524 mm (60 inches). | A, B, C, D, E, F, G |

| Reflex reflector (rear side) | 2 | Red | One on each side (rear) | As far to the rear as practicable. | Both on the same level, between 381 mm (15 inches) and 1,524 mm (60 inches). | A, B, D, F, G |

| Reflex relector (front side)16 | 2 | Amber | One on each side (front) | As far to the front as practicable. | Between 381 mm (15 inches) and 1,524 mm (60 inches). | A, B, C, D, F, G |

| License plate lamp (rear)11 | 1 | White | At rear license plate to illuminate the plate from the top or sides | As far to the front as practicable. | No requirements | A, B, C, D, F, G |

| Side marker lamp (front)16 | 2 | Amber | One on each side |

| Not less than 381 mm (15 inches). | A, B, C, D, F |

| Side marker lamp intermediate | 2 | Amber | One on each side | At or near the midpoint between the front and rear side marker lamps, if the length of the vehicle is more than 9,144 mm (30 feet). | Not less than 381 mm (15 inches). | A, B, D, F, G |

| Side marker lamp (rear)4, 8 | 2 | Red | One on each side | As far to the rear as practicable. | Not less than 381 mm (15 inches), and on the rear of trailers not more than 1,524 mm (60 inches). | A, B, D, F, G |

| Turn signal (rear)5, 12 | 2 | Amber or red | Rear | One lamp on each side of the vertical centerline as far apart as practicable. | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches). | A, B, C, D, E, F, G |

| Identification lamp (rear)3, 7, 15 | 3 | Red | Rear | One as close as practicable to the vertical centerline. One on each side with lamp centers spaced not less than 152 mm (6 inches) or more than 305 mm (12 inches) apart. | All three on the same level as close as practicable to the top of the vehicle. | B, D, G |

| Vehicular hazard warning signal flasher lamps5, 12 | 2 | Amber | Front | One lamp on each side of the vertical centerline, as far apart as practicable. | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches). | A, B, C |

| 1 or 2 | Amber or red | Rear | One lamp on each side of the vertical centerline, as far apart as practicable. | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches). | A, B, C, D, E, F, G | |

| Backup lamp14 | 1 or 2 | White | Rear | Rear | No requirement | A, B, C |

| Parking lamp | 2 | Amber or white | Front | One lamp on each side of the vertical centerline, as far apart as practicable. | Both on the same level, between 381 mm (15 inches) and 2,108 mm (83 inches). | A |

| Legend: Types of commercial motor vehicles shown in the last column of Table 1: A. Buses and trucks less than 2,032 mm (80 inches) in overall width. Note: Lamps and reflectors may be combined as permitted by equipment combinations. | ||||||

| NOTES: 1Identification lamps and reflectors may be mounted on the vertical centerline of the cab where different from the centerline of the vehicle, except where the cab is not more than 42 inches wide at the front roofline, then a single lamp at the center of the cab shall be deemed to comply with the requirements for identification lamps. No part of the identification lamps or their mountings may extend below the top of the vehicle windshield. 2Unless the turn signals on the front are so constructed (doubled-faced) and located as to be visible to passing drivers, two turn signals are required on the rear of the truck tractor, one at each side as far apart as practicable. 3The identification lamps need not be visible or lighted if obscured by a vehicle in the same combination. 4Any semitrailer or full trailer manufactured on or after March 1, 1979, shall be equipped with rear side-marker lamps at a height of not less than 381 mm (15 inches), and on the rear of the trailers not more than 1,524 mm (60 inches) above the road surface, as measured from the center of the lamp on the vehicle at curb weight. 5Each converter dolly, when towed singly by another vehicle and not as part of a full trailer, shall be equipped with one stop lamp, one tail lamp, and two reflectors (one on each side of the vertical centerline, as far apart as practicable) on the rear. Each converter dolly shall be equipped with rear turn signals and vehicular hazard warning signal flasher lamps when towed singly by another vehicle and not as part of a full trailer, if the converter dolly obscures the turn signals at the rear of the towing vehicle. 6Pole trailers shall be equipped with two reflex reflectors on the rear, one on each side of the vertical centerline as far as practicable, to indicate the extreme width of the trailer. 7Pole trailers, when towed by motor vehicles with rear identification lamps and mounted at a height gre ater than the load being transported on the pole trailer, are not required to have rear identification lamps. 8Pole trailers shall have on the rearmost support for the load: (1) two front clearance lamps, one on each side of the vehicle, both on the same level and as high as practicable to indicate the overall width of the pole trailer; (2) two rear clearance lamps, one on each side of the vehicle, both at the same level and as high as practicable to indicate the overall width of the pole trailer; (3) two rear side marker lamps, one on each side of the vehicle, both on the same level, not less than 375 mm (15 inches) above the road surface; (4) two rear reflex reflectors, one on each side, both on the same level, not less than 375 mm (15 inches) above the road surface to indicate maximum width of the pole trailer; and (5) one red reflector on each side of the rearmost support for the load. Lamps and reflectors may be combined. 9Any motor vehicle transporting a load that extends more than 102 mm (4 inches) beyond the overall width of the motor vehicle shall be equipped with the following lamps in addition to other required lamps when operated during the hours when headlamps are required to be used. (1) The foremost edge of that portion of the load that projects beyond the side of the vehicle shall be marked (at its outermost extremity) with an amber lamp visible from the front and side. (2) The rearmost edge of that portion of the load that projects beyond the side of the vehicle shall be marked (at its outermost extremity) with a red lamp visible from the rear and side. (3) If the projecting load does not measure more than 914 mm (3 feet) from front to rear, it shall be marked with an amber lamp visible from the front, both sides, and rear, except that if the projection is located at or near the rear it shall be marked by a red lamp visible from front, side, and rear. 10Projections beyond rear of motor vehicles. Motor vehicles transporting loads that extend more than 1,219 mm (4 feet) beyond the rear of the motor vehicle, or that have tailboards or tailgates extending more than 1,219 mm (4 feet) beyond the body, shall have these projections marked as follows when the vehicle is operated during the hours when headlamps are required to be used: (1) On each side of the projecting load, one red side marker lamp, visible from the side, located so as to indicate maximum overhang. (2) On the rear of the projecting load, two red lamps, visible from the rear, one at each side; and two red reflectors visible from the rear, one at each side, located so as to indicate maximum width. 11To be illuminated when tractor headlamps are illuminated. 12Every bus, truck, and truck tractor shall be equipped with a signaling system that, in addition to signaling turning movements, shall have a switch or combination of switches that will cause the two front turn signals and the two rear signals to flash simultaneously as a vehicular traffic signal warning. The system shall be capable of flashing simultaneously with the ignition of the vehicle on or off. 13To be actuated upon application of service brakes. 14Backup lamp required to operate when bus, truck, or truck tractor is in reverse. 15(1) For the purposes, the term "overall width" refers to the nominal design dimension of the widest part of the vehicle, exclusive of the signal lamps, marker lamps, outside rearview mirrors, flexible fender extensions, and mud flaps. (2) Clearance lamps may be mounted at a location other than on the front and rear if necessary to indicate the overall width of a vehicle, or for protection from damage during normal operation of the vehicle. (3) On a trailer, the front clearance lamps may be mounted at a height below the extreme height if mounting at the extreme height results in the lamps failing to mark the overall width of the trailer. (4) On a truck tractor, clearance lamps mounted on the cab may be located to indicate the width of the cab, rather than the width of the vehicle. (5) When the rear identification lamps are mounted at the extreme height of a vehicle, rear clearance lamps are not required to be located as close as practicable to the top of the vehicle. 16A trailer subject to this part that is less than 1,829 mm (6 feet) in overall length, including the trailer tongue, need not be equipped with front side marker lamps and front side reflex reflectors. 17A boat trailer subject to this part whose overall width is 2,032 mm (80 inches) or more need not be equipped with both front and rear clearance lamps provided an amber (front) and red (rear) clearance lamp is located at or near the midpoint on each side so as to indicate its extreme width. | ||||||

Statutory Authority

§ 46.2-1165 of the Code of Virginia.Historical NotesDerived from VR545-01-07 § 43, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012.

19VAC30-70-440. Service brakes.

A. The inspector, at a minimum, must drive all vehicles into the inspection lane and test both service and parking brakes, except vehicles the inspector is not qualified to drive. In these cases, the inspector will ride in the vehicle and observe the application of the brakes.

B. A minimum of one wheel or one wheel and drum or dust cover must be removed from each vehicle at the time of inspection except vehicles having open brake mechanisms that will permit the inspection of the brake lining, or discs and disc pads, without removing the wheel and rim.

WARNING: Failure to properly torque lug nuts may cause severe damage to the wheel.

The inspection receipt (approval and rejection) shall be marked to reflect which wheel and drum or dust cover was removed or inspected.

C. If any braking problem is detected, the inspector may test drive or require a test drive of the vehicle.

D. Inspect for and reject if:

1. Any commercial motor vehicle manufactured on or after October 20, 1994, is equipped with an air brake system but is not equipped with the proper and functioning automatic brake adjuster system and brake adjuster indicator.

2. Vehicles equipped with air brakes: when the air brake adjustment on vehicles is equal to or exceeds values in the following tables for cam brakes or brake shoe travel is greater than 1/16" on wedge brakes when measured according to Illustrations #1 and #2. (See procedure in addition to illustrations.)

|

| TABLE 1 Brake adjustment shall not exceed those specifications contained hereunder relating to "Brake adjustment limit." (Dimensions are in inches.) | ||

|

| CLAMP TYPE BRAKE CHAMBER DATA | ||

|

| Type | Outside Diameter | Brakes Exceeding the Maximum Brake Adjustment Limit Shall be Readjusted |

|

| 6 | 4-1/2 (114mm) | 1-1/4 (32mm) |

|

| 9 | 5-1/4 (133mm) | 1-3/8 (35mm) |

|

| 12 | 5-11/16 (145mm) | 1-3/8 (35mm) |

|

| 16 | 6-3/8 (162mm) | 1-3/4 (45mm) |

|

| 20 | 6-25/32 (172mm) | 1-3/4 (45mm) |

|

| 24 | 7-7/32 (184mm) | 1-3/4 (45mm) |

|

| 30 | 8-3/32 (206mm) | 2.0 (51mm) |

|

| 36 | 9.0 (229mm) | 2-1/4 (57mm) |

|

| NOTE: A brake found at the adjustment limit is not to be rejected. | ||

|

| LONG STROKE CLAMP TYPE BRAKE CHAMBER DATA | ||

|

| Type | Outside Diameter | Brakes Exceeding the Maximum Brake Adjustment Limit Shall be Readjusted |

|

| 12 | 5-11/16 (14.5mm) | 1-3/4 (45mm) |

|

| 16 | 6-3/8 (162mm) | 2.0 (51mm) |

|

| 20 | 6-25/32 (172mm) | 2.0 (51mm) |

|

| 24 | 7-7/32 (184mm) | 2.0 (51mm) |

|

| 24* | 7-7/32 (184mm) | 2.5 (64mm) |

|

| 30 | 8-3/32 (206mm) | 2.5 (64mm) |

|

| *For 3" maximum stroke type 24 chambers | ||

|

| NOTE: A brake found at the adjustment limit is not to be rejected. NOTE: 3" long stroke brake chambers are identified by square air line ports and a trapezoidal tag attached to the chamber. | ||

|

| BOLT TYPE BRAKE CHAMBER DATA | ||

|

| Type | Outside Diameter | Brakes Exceeding the Maximum Brake Adjustment Limit Shall be Readjusted |

|

| A (12) | 6-15/16 (176mm) | 1-3/8 (35mm) |

|

| B (24) | -3/16 (234mm) | 1-3/4 (45mm) |

|

| C (16) | 8-1/16 (205mm) | 1-3/4 (45mm) |

|

| D (6) | 5-1/4 (133mm) | 1-1/4 (32mm) |

|

| E (9) | 6-3/16 (157mm) | 1-3/8 (35mm) |

|

| F (36) | 11.0 (279mm) | 2-1/4 (57mm) |

|

| G (30) | 9-7/8 (251mm) | 2.0 (51mm) |

|

| NOTE: A brake found at the adjustment limit is not to be rejected. | ||

|

| ROTOCHAMBER DATA | ||

|

| Type | Outside Diameter | Brakes Exceeding the Maximum Brake Adjustment Limit Shall be Readjusted |

|

| 9 | 4-9/32 (109mm) | 1-1/2 (38mm) |

|

| 12 | 4-13/16 (122mm) | 1-1/2 (38mm) |

|

| 16 | 5-13/32 (138mm) | 2.0 (51mm) |

|

| 20 | 5-15/16 (151mm) | 2.0 (51mm) |

|

| 24 | 6-13/32 (163mm) | 2.0 (51mm) |

|

| 30 | 7-1/16 (180mm) | 2-1/4 (57mm) |

|

| 36 | 7-5/8 (194mm) | 2-3/4 (70mm) |

|

| 50 | 8-7/8 (226mm) | 3.0 (76mm) |

|

| NOTE: A brake found at the adjustment limit is not to be rejected. | ||

|

| DD-3 BRAKE CHAMBER DATA | ||

|

| Type | Outside Diameter | Brakes Exceeding the Maximum Brake Adjustment Limit Shall be Readjusted |

|

| 30 | 8-1/8 (206mm) | 2-1/4 (57mm) |

|

| NOTE: This chamber has three air lines and is found on motor coaches. NOTE: A brake found at the adjustment limit is not to be rejected. | ||

|

| WEDGE BRAKE DATA | ||

|

| The combined movement of both brake shoe lining scribe marks shall not exceed 1/8 inch (3.18mm). | ||

PROCEDURE FOR MEASURING CAM AND WEDGE BRAKES AND HOW TO PROPERLY IDENTIFY 3" LONG STROKE CHAMBERS

On vehicles equipped with cam brakes, mark each brake chamber push rod at the face of the brake chamber with the brakes released. Apply the air brakes fully, minimum air pressure of 90 to 100 psi, and measure the distance the push rod travels from the face of the chamber to the mark previously made when the brakes were released. This measurement is the push-rod stroke (see illustration).

On vehicles equipped with wedge brakes, remove the inspection hole cover at each dust shield and with the brakes released, scribe a line on the edge of the brake lining. Apply the air brakes fully and measure the distance the brake lining travels.

3. Brake hose and tubing. There is any leakage in any hydraulic, air or vacuum lines; hoses have any cracks, crimps, restrictions, or are abraded exposing fabric into second ply of fabric; tubing or connections leak, are crimped, restricted, cracked, or broken.

a. Hose with any damage extending through the reinforcement ply. Rubber impregnated fabric cover is not a reinforcement ply. Thermoplastic nylon may have braid reinforcement or color difference between cover and inner tube. Exposure of second color is cause for rejection.

b. Bulge or swelling when air pressure is applied.

c. Two hoses improperly joined (such as a splice made by sliding the hose ends over a piece of tubing and clamping the hose to the tube).

d. Brake tubing and hose must:

(1) Be long and flexible enough to accommodate without damage all normal motions of the parts to which it is attached;

(2) Be secured against chaffing, kinking, or other mechanical damage; and

(3) Be installed in a manner that prevents it from contacting the vehicle's exhaust system or any other source of high temperatures.

e. Any hydraulic brake tubing has been repaired using a compression fitting.

4. Service brakes.

a. There is less than 1/5 reserve in pedal travel of the service brake when fully applied on all hydraulic, mechanical, or power-assisted hydraulic braking systems.

b. When tested on dry, hard, approximately level road free from loose material at a speed of 20 miles per hour without leaving a 12-foot wide lane, a distance in excess of the following stopping distance is obtained:

Any bus, truck or tractor - 40 feet;

All combinations of vehicles - 40 feet.

c. Every motor vehicle, trailer or semitrailer is not equipped with operational brakes on all wheels (except as shown in subdivision D 4 c (1) of this section) or any brake has been disconnected or rendered inoperative or improperly installed.

(1) Road tractors, tractor trucks, or trucks if manufactured prior to July 25, 1980, having three or more axles are not required to have brakes on the steering axle; however, if installed must be inspected and meet all requirements of this section.

(2) Missing, bent or broken mechanical components including: shoes, lining pads, spring, anchor pin, spiders, cam rollers, push rods and air chamber mounting bolts, air reservoirs not securely mounted or leaks.

(3) Absence of braking action on any axle required to have brakes, upon application of the service brakes (such as missing brakes or brake shoes, failing to move upon application of a wedge, S-cam or disc brake).

(4) Loose brake components including air chambers, spiders and cam shaft support brackets.

(5) Audible air leak at brake chamber (example: ruptured diaphragm, loose chamber clamp, etc.)

d. Linings or pads are broken or cracked so that brake pad is not firmly attached to the shoe or improperly installed or cracks on the friction surface extends to the open edge.

(1) Rivets or bolts are loose or missing.

(2) Lining or pad friction surface is saturated with oil, grease or brake fluid.

e. Nonsteering axles. Lining has a thickness less than 1/4 inch at the shoe center for air drum brakes, 1/16 inch or less at the shoe center for hydraulic and electric drum brakes and less than 1/8 inch for air disc brakes, lining with a thickness less than 3/16 inch for a shoe with a continuous strip of lining or to wear indicators if so equipped.

(1) Steering axles. Lining has thickness less than 1/4 inch at the shoe center from drum brakes, less than 1/8 inch for air disc brakes and 1/16 inch or less for hydraulic disc and electric brakes, lining with a thickness less than 3/16 inch for a shoe with a continuous strip of lining or to wear indicators if so equipped.

(2) Mismatch across any power unit steering axle of:

(a) Air chamber sizes.

(b) Slack adjuster length.

f. Thickness of riveted or bolted lining is less than 2/32 of an inch above the rivet or bolt head(s).

g. Any lining or pad is misaligned or does not make full contact with the drum or rotor.

5. Brake Drums and Discs.

a. Brake drums or brake discs (rotors) are worn or scored to the extent that their remachining would result in a failure to meet manufacturer's specifications.

b. Brake drums or discs with any external crack or cracks that open upon brake application.

NOTE: Do not confuse short hairline heat cracks with flexural cracks.

6. Mechanical linkage.

Any portion of the drum or rotor missing or in danger of falling away.

7. Hydraulic.

NOTE: Some motor vehicles, beginning with 1976 models, have a hydraulic power system that serves both the power assisted brakes and power assisted steering system. Some vehicles, beginning with 1985 models, have an integrated hydraulic actuation and anti-lock brake unit using only brake fluid.

8. Hydraulic System Operation.

Stop engine, then depress brake pedal several times to eliminate all pressure. Depress pedal with a light foot-force (30 pounds). While maintaining this force on the pedal, start engine and observe if pedal moves slightly when engine starts.

Reject vehicle if pedal does not move slightly as engine is started while force is on brake pedal.

9. Condition of hydraulic booster power brake system.

Inspect system for fluid level and leaks. Reject vehicle if there is insufficient fluid in the power steering pump reservoir; if there are broken, kinked or restricted fluid lines or hoses; if there is any leakage of fluid at the pump, steering gear or brake booster, or any of the lines or hoses in the system; or if belts are frayed, cracked or excessively worn.

10. Integrated hydraulic booster/anti-lock system operation.

With the ignition key in the off position, depress brake pedal a minimum of 25 times to deplete all residual stored pressure in the accumulator. Depress pedal with a light foot-force (25 lbs.). Place ignition key in the on position and allow 60 seconds for the brake warning light to go out and the electric pump to shut off.

Reject vehicle if the brake pedal does not move down slightly as the pump builds pressure or if the brake and anti-lock warning lights remain on longer than 60 seconds.

11. Condition of integrated hydraulic booster/anti-lock system with electronic pump.

With the system fully charged, inspect system for fluid level and leaks.

Reject vehicle if there is insufficient fluid in the reservoir; if there are broken, kinked or restricted fluid lines or hoses; or if there is any leakage of fluid at the pump or brake booster, or any of the lines or hoses in the system.

12. Vacuum system operation.

Stop engine then depress brake pedal several times to eliminate all vacuum in the system. Depress pedal with a light foot-force (25 lbs.). While maintaining this force on the pedal, start engine and observe if pedal moves down slightly when engine starts.

Reject vehicle if pedal does not move down slightly as engine is started while force is on the brake pedal. In full vacuum-equipped vehicles, there is insufficient vacuum reserve for one full service brake application after engine is stopped.

a. Has insufficient vacuum reserve to permit one full brake application after engine is shut off.

b. Lacks an operative low-vacuum warning device as required.

13. Condition of vacuum booster power brake system.

a. Visual inspection. Reject vehicle if there are collapsed, cracked, broken, badly chafed or improperly supported hoses and tubes, loose or broken hose clamps.

b. There is any leakage in the hydraulic system. (Do not disturb the dust boot when checking for leaking wheel cylinders.)

c. Fluid level in master cylinder is below the proper level for the particular vehicle.

d. There is any evidence of a caliper sticking or binding.

14. Air brakes.

a. Motor vehicle is equipped with air brakes and does not have an operating air pressure gauge.

b. Any bus, truck, road tractor and tractor truck manufactured after March 15, 1975, must have a visible low air warning device. Those manufactured on or before March 15, 1975, may have either an audible or visible low air warning device.

Low pressure warning device is missing, inoperative or does not operate at 55 psi and below or 1/2 the governor cut out pressure, whichever is less.

c. Compressed air reserve is not sufficient to make one full service brake application after engine is stopped, or with system fully charged, the reservoir pressure is lowered more than 30% by one full brake application.

Brake chamber push rods do not follow application of service brake pedal, or do not reach full released position (example: defective return spring).

d. Any bus, truck, road tractor, or tractor truck manufactured after February 28, 1975, if equipped with a manually operated device to reduce or remove the braking effort upon its front wheels.

15. Electric brakes.

a. Trailers show an amperage value more than 20% above or 30% below the brake manufacturer's maximum current rating for each brake.

b. Ammeter shows no reading or indicator is not steady on application and release of brake controller.

c. Any terminal connections are loose or dirty; wires are broken, frayed or unsupported; any single conductor or nonstranded wire or wires below size recommended by brake manufacturers are installed.

d. Electrical trailer brakes do not apply automatically when breakaway safety switch is operated.

e. Absence of braking action on any wheel required to have brakes.

f. Missing or inoperative breakaway braking device; cable is frayed or broken.

16. Air compressor.

a. Compressor drive belts are in condition of impending or probable failure.

b. Loose compressor mounting bolts or compressor leaks.

c. Cracked, broken or loose pulley.

d. Tractor protection valve(s) is defective or inoperative.

e. Air safety relief valve is defective or inoperative.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 44, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 32, Issue 24, eff. October 3, 2016; Errata, 32:26 VA.R. 3588 August 22, 2016.

19VAC30-70-450. Brakes: emergency parking or holding.

A. Some vehicles are equipped with an actual emergency brake, while others have only a parking or holding brake. Some types may be actuated by a foot or hand lever, while others may incorporate a switch or valve to actuate the brake. Air and vacuum brake systems may employ spring activating parking brakes.

B. Inspect for and reject if:

1. Vehicle or combination of vehicles is not equipped with a parking, holding, or emergency brake in good working order of the type installed as original standard factory equipment for the vehicle on which it is installed.

2. The brake actuating mechanism does not fully release when the control is operated to the off position.

3. Any mechanical parts are missing, broken, badly worn, or are inoperative.

4. Cables are stretched, worn, or frayed or not operating freely.

5. Parking brake will not hold the vehicle stationary with the engine running at slightly accelerated speed with shift lever in drive position for automatic transmission or shift lever in low gear with clutch engaged for standard shift transmission.

6. On vehicles equipped with automatic transmissions, the vehicle will start in any gear other than (P) park or (N) neutral. If the gearshift indicator does not identify the park (P) and neutral (N) positions, then the vehicle shall be rejected.

7. On vehicles equipped with manual transmissions, the vehicle will start in any gear if the clutch is not depressed or disengaged.

NOTE: This will not apply to older vehicles, which were not originally equipped with a neutral-safety switch, clutch disengagement system or clutch pedal position sensor by the manufacturer.

8. Any nonmanufactured hole in the spring brake housing section of a parking brake.

NOTE: All commercial motor vehicles manufactured after March 7, 1990, shall be equipped with a parking brake system adequate to hold the vehicle or combination under any condition of loading except agricultural commodity trailers, converter dollies, heavy haulers and pulpwood trailers.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 45, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012; Volume 32, Issue 24, eff. October 3, 2016; Volume 35, Issue 25, eff. September 1, 2019.

19VAC30-70-460. Brakes: trailer (GVWR 10,000 pounds or more).

A. All trailers and semitrailers having an actual gross weight of 10,000 pounds or more shall be equipped with operational brakes acting on all wheels.

B. Inspect for and reject if:

1. Trailer brakes do not comply with provisions of 19VAC30-70-430, 19VAC30-70-440 and 19VAC30-70-450.

2. Operator does not have full control over brakes. For the purpose of this subdivision, surge brakes are considered to be in control of the operator.

3. Combination will not stop as required in 19VAC30-70-440 D 5.

4. Breakaway braking devices are missing or inoperative or cable is frayed or broken, or trailers are not equipped with emergency breakaway brakes designed to:

a. Apply automatically upon breakaway from towing vehicle.

b. Remain fully applied for at least 15 minutes.

c. Apply and release by operation of the manual emergency control.

d. Apply automatically when the pressure in the towing vehicle reservoir is reduced to a point between 45 and 20 PSI by a series of foot applications, when equipped with air brakes.

NOTE: A minimum of one wheel must be removed from each axle equipped with brakes to inspect the brake components.

Exceptions:

a. Wheels on trailers equipped with open brake mechanisms are not required to be removed.

b. The inspection receipt (approval and rejection) shall be marked to reflect which wheel, drum or dust cover was removed or inspected.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 46, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012; Volume 32, Issue 24, eff. October 3, 2016.

19VAC30-70-470. Steering.

Inspect for and reject if:

1. Play at any point in the steering mechanism is excessive. The steering mechanism is unusually tight and binding when turning the steering wheel completely to the right and left. The steering mechanism will not turn in both directions, stop to stop, or steering stops have been removed. On certain model passenger buses, it may be necessary to open the inspection access door to allow visual inspection of the steering shaft universal joints.

2. Power steering is defective and affects adequate steering of the vehicle or fluid level in reservoir is below operating level or if there is an obvious leak of power steering fluid. Do not reject for dampness. Power steering hoses have any cracks, crimps, or restrictions or are abraded, exposing inner fabric; tubing or connections leak or are crimped, restricted, cracked, or broken. Power steering tubing and hoses must be secured against chaffing, kinking, or other mechanical damage and be installed in a manner that prevents contact with the vehicle's exhaust system or any other source of high temperatures. Power steering belt does not have sufficient tension, is frayed, or is missing. The serpentine belt should only be rejected if a chunk of the ribbing is missing or a deep cut or crack exposes the inner fabric of the belt. (Do not reject for the many little surface cracks that appear in the ribs or back.)

NOTE: If the vehicle is equipped with power steering, the engine must be running during testing.

3. Any modification has been made to any part of the steering system that affects proper steering. A repair kit or preventive maintenance kit has been installed on a tie rod end, idler arm, ball joint, or any other part of the vehicle's steering gear.

NOTE: This system requires moving components to be checked for steering wheel lash, loose parts or binding. To properly inspect the power steering components, the engine must be running.

NOTE: The repair kit or preventive maintenance kit usually consists of a small spring and a plastic cap that is placed over the bolt stud of the component and held in place by a retaining nut. There is nothing in this paragraph that prohibits the replacement of parts or components of a motor vehicle's steering gear in order to correct deficiencies in the steering gear.

4. Steering Lash/Travel-Trucks.

Before inspection the vehicle must be placed on a smooth, dry, level surface. For vehicles equipped with power steering, the engine must be running and the fluid level, belt tension and condition must be adequate before testing.

With road wheels in straight ahead position, turn steering wheel until motion can be detected at the front road wheels. Align a reference mark on steering wheel with a mark on a ruler and slowly turn steering wheel in the opposite direction until motion can be detected at the front road wheel. Measure lash at steering wheel. Special lash-checking instruments are also available, measuring free play in inches or degrees. Such instruments should always be mounted and used according to the manufacturer's instructions. With vehicle raised, visually inspect steering linkage, ball studs, tie rod end socket assemblies and all pivot points. On vehicles with power steering, engine must be running.

Reject vehicle if steering wheel movement exceeds:

Steering Wheel Size and Lash

|

| Steering wheel diameter | Manual steering system |

|

| 16 inches or less | 2 inches (51 mm) |

|

| 18 inches | 2 1/4 inches (57 mm) |

|

| 19 inches | 2 3/8 inches (60 mm) |

|

| 20 inches | 2 1/2 inches (64 mm) |

Reject vehicle if visual inspection reveals excessive wear and/or looseness in any ball stud, end assembly, pivot point or mechanical linkage.

|

|

5. Any modification or replacement has been made to the steering wheel which affects proper steering. It shall be rejected if it is of a smaller size than the original factory equipment.

6. Steering column has any missing or loose bolts or positioning parts, resulting in motion of the steering column from its normal position. Steering shaft universal joints are loose or exhibit any abnormal movement when shaft is rotated. Any welded repairs are made to the steering system, steering column, steering gear box, pitman arm or universal joints. Any movement of a steering nut under steering load.

7. Any missing or loose bolts or other parts resulting in motion of the steering gear box at the point of attachment to the vehicle's frame.

8. Any looseness of the pitman arm on the steering gear box, output shaft or gear box.

9. Any control arm bushing is missing.

10. Any vehicle equipped with an idler arm shows excessive looseness.

11. Any motion, other than rotational, between any linkage member and its attachment point of more than 1/8 inch measured with hand pressure only.

12. Loose clamps, clamp bolts on tie rod ends or drag links.

13. Any looseness in any threaded joint.

14. Loose or missing nut on tie rods, pitman arm, drag ink, steering arm or tie rod ends.

15. Wheel bearings/steering linkage.

a. With the front end of vehicle lifted properly, push pads away from rotor on disc brakes, and grab front tire at top and bottom, rock vigorously in and out and record movement. Wheel bearing looseness is detected by the relative movement between the brake drum or disc and the backing plate or splash shield.

(1) Reject vehicle if relative movement between drum and backing plate (disc and splash shield) is more than 1/4 inch measured at the outer circumference of the tire for vehicles more than 10,000 pounds GVWR.

(2) Reject vehicle if any wheel bearing is excessively worn or not properly adjusted; any cotter key or other locking device is missing or inoperative.

b. Steering linkage play. First eliminate all wheel bearing movement by applying service brake. With vehicle lifted as shown below and wheels in straight ahead position, grasp front and rear of tire and attempt to move assembly right and left without moving the steering gear.

Reject vehicle if measured movement at front or rear of tire is greater than:

|

| Wheel size: | 17 inches or less | - 1/4 inch (6.5mm) |

|

|

| 17 to 18 inches | - 3/8 inch (9.5mm) |

|

|

| over 18 inches | - 1/2 inch (13mm) |

|

|

| ||

c. King pin. If vehicle is equipped with king pins, first eliminate all wheel bearing movement by applying service brake. With front end lifted as illustrated for inspecting wheel bearings, (Figure C) grasp the tire at the top and bottom and attempt to move in and out to detect looseness. Measure the movement at the top or bottom of the tire at the outer circumference.

Reject vehicle if measured movement at top or bottom of tire is greater than:

|

| Wheel size: | 16 inches or less | - 1/4 inch | ||

|

|

| 17 to 18 inches | - 3/8 inch | ||

|

|

| over 18 inches | - 1/2 inch | ||

|

|

| ||||

|

| Proper lifting for wheel bearing, steering linkage looseness, and king play action | ||||

|

| FIGURE A | FIGURE B | FIGURE C | ||

|

|

|

|

|

|

|

NOTE: Ball joint wear: There is a trend among U.S. automobile manufacturers toward the use of "wear-indicating" ball joints on light trucks. Many vehicles on the road, however, do not have wear-indicating ball joints. The inspection of both types will be discussed.

Figures 1, 2, 3 and 4 below illustrate the proper hoisting for checking ball joints.

|

|

|

a. NOTE: To check ball joint wear on vehicles when the spring is supported on the upper control arm or when the spring is a part of a MacPherson strut or wear in any other type suspension not using ball joints when the front wheels are suspended on a solid axle, the vehicle must be hoisted as shown in Figure 1 or 2.

b. NOTE: Upper control arm must be stabilized in normal load carrying position by means of an upper control or other support tool to insure ball joint is in unloaded position.

c. NOTE: To check ball joint wear on vehicles not listed in Figures 1 through 4 and diagram or tables when the spring is supported on the lower control arm; and to check the kingpin wear in any other type suspension not previously described when the wheels are independently suspended, the vehicle must be hoisted as shown in Figure 3 or 4.

16. Vehicles without wear indicator ball joint.

a. If play is detected in any ball joint without "wear-indicating" ball joints, it will be necessary for the inspection to be made in accordance with the manufacturer's recommended procedures and specifications prior to rejecting the vehicle.

b. If there are no manufacturer's recommended procedures and specifications, the lower ball joints will be checked when hoisted as in Figure 1 or 2, or in the upper ball joints when hoisted as in Figure 3 or 4. There should be no noticeable play detected in the ball joints when checked in this manner.

c. Reject vehicle if play exceeds the manufacturer's specifications. It is recommended that inspectors use a dial indicator or ball joint checking gauge when checking for play of a ball joint when procedures and specifications are provided by the manufacturer.

17. Ball joints with wear indicators. Support vehicle with ball joints loaded (in normal driving attitude). Wipe grease fitting and checking surface free of dirt and grease. Determine if checking surface extends beyond the surface of the ball joint cover.

Reject vehicle if checking surface is flush with or inside the cover surface.

|

|

18. Any vehicle inspected in accordance with the recommendation of the manufacturer of such vehicle and found to be within the specification shall be deemed to meet inspection regulations.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.Historical NotesDerived from VR545-01-07 § 47, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Errata, 25:3 VA.R. 543 October 13, 2008; amended, Virginia Register Volume 32, Issue 24, eff. October 3, 2016; Errata, 32:26 VA.R. 3588 August 22, 2016.

19VAC30-70-480. Suspension.

Inspect for and reject if:

1. Any positioning parts are cracked, broken, loose, or missing resulting in shifting of an axle from its normal position.

2. Any part of the torsion bar assembly or torque arm or any part used for attaching the same to the vehicle frame or axle is cracked, broken or missing.

NOTE: This does not apply to loose bushing(s) in torque or track arms.

3. Vehicles designed for shock absorbers or cross stabilizer links, if any are missing, disconnected, broken, bent, loose or do not function properly.

4. Any leaf spring is broken, sagging, misaligned, or if spring hangers are worn or loose.

5. Any deflated air suspension system or leaks.

CAUTION: Underneath inspection of a vehicle equipped with air suspension with excessive leakdown could result in serious personal injury.

6. Any suspension system defect or any condition of loading that permits the body or frame to come in contact with a tire or any part of the wheel assemblies.

NOTE: "All thread rod" material shall not be used as U-bolts in the suspension system.

7. Sliding trailer tandem or multi-axle assemblies do not lock in place or have broken or missing parts.

8. Any coil spring is broken.

9. Vehicles with composite springs on either the power unit or trailer, if a crack, regardless of length, is visible on either side, top or bottom.

NOTE: A crack is a separation in any axis that passes completely through the spring.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 48, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 32, Issue 24, eff. October 3, 2016.

19VAC30-70-490. Frame, engine mounts, coupling devices and emergency chains.

Inspect for and reject if:

1. Frame of any bus, truck, tractor truck is cracked, loose, broken or sagging. Frame of any trailer or semi-trailer has any broken cracked, loose, or sagging top or bottom frame rails or frame is cracked or broken.

2. Engine, transmission or cab mounts, to include all hardware, bolts, and bushings used to connect the mount to the vehicle, frame, engine, or transmission are broken or missing. Any engine or transmission mount shall be rejected if it allows the power train to come in contact with the firewall or other body parts. Cab mounts should be rejected if they do not properly secure the body to the frame.

3. Trailer hitch or pintle hook is not securely attached. Reject if the pintle eye or trailer drawbar has any cracks or if any welding repairs have been made to the pintle eye.

4. Chains, cables, etc., used to attach a towed vehicle are not securely attached, or are broken, worn or abraded.

5. Fifth wheel does not lock in position or have a locking mechanism that is in proper working order.

NOTE: Reject if horizontal movement exceeds 1/2 inch between upper and lower fifth wheel halves.

6. Fifth wheel assembly system has any leak of fluid or air.

7. Fifth wheel has any broken, missing, or damaged parts; or is not securely attached to the frame. This includes fore and aft stops.

8. Trailer king pin is not secure, or is broken, or worn so as to prevent secure fit in fifth wheel. The upper coupler device is not securely attached.

9. Any cracks, breaks or damaged parts in the stress or load bearing areas of a coupling device.

10. Trailer is not equipped with emergency chains or steel cables.

NOTE: Fifth wheel assembly does not require emergency chain or steel cable. A fifth wheel is defined as a device that interfaces with and couples to the upper coupler assembly of a semitrailer. The upper coupler assembly is a structure consisting of an upper coupler plate, king pin and supporting framework which interfaces with and couples to a fifth wheel. Ball and socket connections also referred to as hitch and coupling connections are not fifth wheel assemblies and do require an emergency chain or steel cable.

11. Sliding trailer tandem or multi-axle assemblies do not lock in place or have worn, broken or missing parts.

12. Any play is detected in the drive shaft u-joints, CV joints, or center load bearing.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.Historical NotesDerived from VR545-01-07 § 49, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 12, Issue 21, eff. August 7, 1996; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012; Errata, 28:25 VA.R. 2077 August 13, 2012; amended, Virginia Register Volume 32, Issue 24, eff. October 3, 2016; Volume 35, Issue 25, eff. September 1, 2019.

19VAC30-70-500. Tires, wheels, rims.

Inspect for and reject if:

1. Any tire is marked specifically for use other than on the highway, such as "For Farm Use Only," "For Off-Highway Use Only," any tire marked "Not for Steering Axle," "For Mobile Home Use Only," or "For Trailer Use Only."

EXCEPTION: "For Trailer Use Only" tires are allowed when used on trailers only.

2. A radial tire is mismatched on the same axle with a bias ply tire or a bias belted tire.

3. Bias ply or bias belted tires are used on the rear axle when radial ply tires are used on the front axle. Except:

a. On a two-axle vehicle equipped with truck tires with 20-inch rim diameter and larger. Bias or radial tires may be used on either axle if the vehicle has dual rear wheels or is equipped with wide-base single tires.

b. Either bias or radial tires may be used on the steering axle of vehicles with three or more axles.

4. Bias tires and radial tires are mixed in a tandem-drive axle combination on a vehicle equipped with truck tires with 20-inch rim diameter and larger.

5. Any tire on the front wheel of a bus, truck or any tractor truck has a tread groove pattern of less than 4/32 inch when measured at any point on a major tread groove.

6. Any bus has regrooved, recapped, or retreaded tires on the front wheels.

7. Any motor vehicle, trailer or semitrailer, except the dual wheels installed on motor vehicles having seats for more than seven passengers: (i) operated wholly within a municipality, or (ii) operated by urban and suburban bus lines, which are defined as bus lines operating over regularly scheduled routes and the majority of whose passengers use the buses for traveling a distance of not exceeding 40 miles, measured one way, on the same day between their place of abode and their place of work, shopping areas, or schools, is equipped with a tire that has a tread depth measuring less than 2/32 of an inch when measured as follows: NOTE: The exemptions provided in clauses (i) and (ii) of this subdivision do not apply to buses owned or operated by any public school district, private school, or contract operator of buses.

NOTE: Measure in two adjacent tread grooves where tread is thinnest. If either of the grooves measure 2/32 of an inch or more, no further measurements are necessary and tread depth is satisfactory. Do not measure on tread wear indicators.

If both adjacent grooves measure less than 2/32 of an inch, the tire tread depth must be measured again at two additional equally spaced intervals around the circumference of the tire in a like manner as the first measurement. If the tread depth is less than 2/32 of an inch in two adjacent tread grooves at each of the equally spaced intervals, the tire must be rejected.

NOTE: Refer to Figures 1, 2, 3, and 4 in this section for illustrations of how to measure tire tread.

|

| MEASURE WHERE THE TREAD IS THINNEST IN TWO ADJACENT TREAD GROOVES

IF THE DEPTH IS LESS THAN 2/32-INCH IN BOTH GROOVES MEASURE AT TWO ADDITIONAL EQUALLY SPACED INTERVALS |

8. A tire equipped with tread wear indicators if found to have such indicators in contact with the pavement in any two adjacent grooves at three equally spaced intervals around the circumference of the tire. Refer to Figure 2.

|

| REJECT IF THE TREAD WEAR INDICATORS ARE IN CONTACT WITH THE PAVEMENT IN ANY TWO ADJACENT GROOVES AT THREE EQUALLY SPACED LOCATIONS

|

9. Any tire has a cut to the extent a ply or belt material is exposed or puncture, not to include a plug or patch that may be used as a manner of repair.

NOTE: Plugs or patches shall be in the tread area only. Plugs or patches are not permitted in the sidewall of the tire.

10. Any tire is worn so that the fabric or steel cord is visible.

11. Any tire has knots or bulges in its sidewalls or if there is evidence of a broken belt under the tread, or if the tread is separating from the fabric.

12. Any tire that has been recut or regrooved except commercial tires so designed and constructed to provide for acceptable and safe recutting and regrooving. Each tire that has been regrooved must be labeled with the word "Regroovable" molded on or into the tire on both sidewalls in raised or recessed letters.

13. Any tire is flat or has an audible air leak.

14. Any tire so mounted or inflated that it comes into contact with its mate or any parts of the vehicle.

15. Rims, or lock rings or wheels are bent, cracked or damaged so as to affect safe operation of the vehicle. Reject if lug nut holes are elongated (out of round).

16. Any wheel studs, bolts, nuts, lugs, or other fasteners (both spoke and disc wheels) are loose, broken, cracked, stripped, missing, or damaged or otherwise ineffective.

17. Any welded repair on aluminum wheels on a steering axle or any welded repair (other than disc to rim attachment) on steel drive wheels mounted on the steering axle.

18. Directional tires or wheels, designed and manufactured to go in a certain direction of rotation not installed in the proper direction of rotation.

|

|

|

|

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 50, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 12, Issue 21, eff. August 7, 1996; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012; Volume 32, Issue 24, eff. October 3, 2016; Volume 35, Issue 25, eff. September 1, 2019.

19VAC30-70-510. Headlamps.

A. Inspect for and reject if:

1. Any motor vehicle is not equipped with at least two headlamps of an approved type. The headlamps must be marked with the headlamp manufacturer's name or trademark, and DOT. If the headlamp bulbs are replaceable, the headlamp lens must be marked with the headlamp light source type (bulb) for which it was designed and the bulb must match the lens code.

NOTE: If the headlamp system is stamped to accept halogen bulbs, then the replacement bulbs must be halogen as well. Retrofitting an HID or LED bulb to a halogen headlamp system does not conform to the standards set forth by the Federal Motor Vehicle Safety Standards (FMVSS) and shall be rejected.

If the entire headlamp assembly is changed from a halogen system to an LED system and does not require the manufacture's original wiring to be cut or compromised, then it shall be considered for inspection if it meets the requirements of subdivision A 2 of this section.

2. Headlights are not of the same approved type (Halogen, HID, LED, etc.) except for sealed beam headlamps, or the replacement headlamp system does not contain all properly marked DOT and SAE stamps certifying that it has met and complied with the standards set forth by the Federal Motor Vehicle Safety Standard (FMVSS) 108.

NOTE: Replacement headlamps stamped with a DOT or SAE approval shall be considered approved by the Superintendent of State Police and will not be required to be listed on the Virginia Motor Vehicle Approved Equipment List.

3. In any headlamp the lens is cracked, broken, discolored, or rotated away from the proper position, or the reflector is not clean and bright.

4. Moisture or water buildup in headlamp is such that it affects the aiming pattern.

5. Headlamps emit light other than white. Light tints of color may be acceptable if the headlamp and headlamp bulbs are marked as required.

6. Bulbs are not of an approved type and marked with all of the following: light source type, the manufacturer's name or trade mark, and DOT.

a. Approved headlamp bulbs: HB1, HB2, HB3, HB3A, HB4, HB4A, HB5, H1, H3, H7, H8, H8B, H9, H9B, H9C, H11, H11B, H11C, H13, H13C, H15, HIR1, HIR2, H18, H19.

b. Approved headlamp bulbs that require ballast: 9500, D1R, D1S, D2R, D2S, D3R, D3S, D4R, D4S, D5S, D7S, D8S, D9S.

c. Approved headlamp ballasts must be marked with the light source type (bulb) and DOT. The bulb type marked on the ballast must match the marking on the headlamp lens.

7. Any filament or bulb in headlamps fails to burn properly or headlamps are not at the same location or configuration as designed by the manufacturer. (Location and type of headlamps can be found in subsection B of this section.)

8. Wiring is dangling or connections are loose, or if proper filaments do not burn at different switch positions, or if switches, including foot or hand dimmer, do not function properly, and are not convenient to the driver.

9. Foreign material is placed on or in front of the headlamp lens or interferes with the beam from the lamp. No glazing may be placed over or in front of the headlamps unless it is a part of an approved headlamp assembly. Reject if the vehicle has wire, unapproved plastic covers, any other materials that are not original equipment or any colored material placed on or in front of the headlamps.

EXCEPTION: A clear impact film known as Headlight Savers produced by Grand Prix Motoring Accessories may be applied to the headlight lens to absorb impact of rocks, etc.

EXCEPTION: A law-enforcement special weapons and tactics (SWAT) or tactical armored vehicle, designed and manufactured exclusively for missions, may apply protective bars in front of the headlamps when designed and installed by the manufacturer.

NOTE: Headlamps, auxiliary driving lamps and front fog lamps shall be mounted so that the beams are aimable and the mounting shall prevent the aim of the lighting device from being disturbed while the vehicle is operating on public roads. All lamps shall be securely mounted on a rigid part of the vehicle.

10. Lamps can be moved easily by hand due to a broken fender or loose support, or if a good ground is not made by the mounting.

Headlamps, auxiliary driving lamps and front fog lamps shall be mounted so that the beams are aimable and the mounting shall prevent the aim of the lighting device from being disturbed while the vehicle is operating on public roads. All lamps shall be securely mounted on a rigid part of the vehicle.

11. A headlamp visor is over two inches long unless part of the original body design.

12. The beam indicator in the driver's compartment does not burn when the high beam is on. (Vehicles not originally equipped with an indicator are not required to comply unless sealed beam headlamps have been installed.)

13. Headlamps are not aimed within the following tolerances using optical aimer:

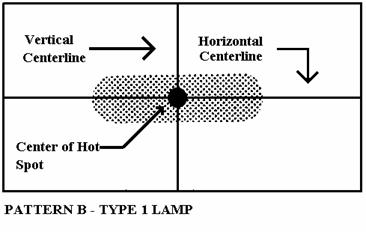

a. The center of the hot spot of all Type 1 lamps, all single element high beam lamps, and all lamps that do not have Type 2 embossed in the lens, is set more than four inches up or down from the horizontal centerline or more than four inches to the left or right from the vertical centerline.

b. The left edge of the lamp pattern of any low beam lamp or any combination or multi-element lamp or Type 2 lamp is more than four inches to the left or right of the vertical centerline or the top edge of the lamp pattern is more than four inches above or below the horizontal centerline.

Aiming the Headlamps:

Inspectors shall rely on their education, training, and experience to determine if the headlamps are properly aimed. If improper alignment is observed, headlamps shall be checked for proper aim by using an optical headlamp aimer except on vehicles equipped with on-board aimers.

Headlamp aim on vehicles with on-board aimers shall be checked by visually examining the leveling device mounted either on or adjacent to the headlamp. Reject the vehicle if the leveling device shows the headlamp adjustment to exceed indicated specifications.

NOTE: Driving lamps and fog lamps must be visually inspected to ensure proper aiming. If improper alignment is observed, the optical aimer shall be used to correct any misalignment.

Optical Aimer:

NOTE: Optical aimers must be properly calibrated and used in the manner recommended by the manufacturer.

NOTE: When aiming headlamps, first look for the type of lamp, which will be found embossed on the lens. The type determines which aiming requirements must be followed for the optical aimer.

NOTE: All Type 2 headlamps and all low beam or multi-element headlamps must be set by aiming the lamp pattern with the lamps set on low beam.

NOTE: If attempting to align a composite or sealed beam lamp with a high and low beam within the same housing, align only the low beam. If aligning a four-lamp system with high and low beams in separate housings, it may be necessary to cover the low beam while aligning the high beam, if all four lamps are on at the same time.

NOTE: Pattern should be aimed so that the left edge does not extend to the left or right of straight ahead, and the top of the pattern should be even with the horizontal.

NOTE: All VOL and VOR headlamps will be aimed as follows:

To properly aim a combination multi-element or low beam VOL or VOR headlamp assembly, the headlamp pattern should be aimed on low beam only.

Letters marked on the headlamp cover should properly identify VOL and VOR headlamps.

NOTE: VOL and VOR headlamps will normally have only one adjustment, which will be for the vertical aim only. The horizontal aim should be disregarded, as the horizontal aim is preset at the factory.

Pattern "A" represents the light pattern, as it should appear on the view screen of the approved aimer when checking the low beam pattern on a single element headlamp or a combination multi-element headlamp.

|

NOTE: All Type 1 headlamps and all headlamps that do not have Type 2 embossed in the lens shall be set by aiming the center of the hot spot with the lamps set on high beam.

NOTE: Aim straight ahead-center of the hot spot should be centered with the vertical and horizontal centerlines.

Pattern "B" represents the light pattern as it should appear on the view screen of the approved aimer.

|

NOTE: The four headlamp system combines four 5-3/4-inch lamps in pairs.

NOTE: One lamp embossed at the top as Type "1" and one embossed on the top as a Type "2" are arranged as a pair on each side.

NOTE: When lamp pairs are mounted horizontally, the Type "2" lamp must be on the outer side.

NOTE: The four headlamp system must be wired so that only the lower beam in the Type "2" lamps will burn when the light beams are depressed. When switched to high beams, both the Type "1" and Type "2" will burn.

NOTE: Light patterns shown on the following page will be displayed on the most recently approved light machines produced by Hopkins and Symtech Corporations.

Aiming the Headlamps:

NOTE: All headlamps that are found not to be within the four-inch tolerance shall be adjusted to zero inches up or down and zero inches to the right or left.

Headlamps on Vehicles used for Snow Removal:

NOTE: Approved auxiliary headlamps (SAE-Z) may be mounted above the conventional headlamps. (These lamps must be in compliance with 19VAC30-70-140, in its entirety, subdivision 7 of 19VAC30-70-150 and subsection A of 19VAC30-70-170 of this manual.)

B. Inspect for and reject if:

1. Lamps are not an approved type as indicated in subdivision A 6 of this section.

2. Lamps are not mounted in a manner that will permit proper aiming.

3. Lamps are mounted so as to obstruct the driver's vision.

4. The auxiliary headlamp circuit does not contain a switch that will deactivate the primary headlamp system when the auxiliary headlamps are in use.

5. Auxiliary headlamps are not aimed in accordance with the provisions of this section.

HEADLAMP PATTERNS

|

|

NOTE: ALWAYS inspect the following sealed beam and replacement bulb headlamps on LOW BEAM only:

5-3/4 inch, marked Type 2 or 2CI

b. 7 inch, marked Type 2 or 2DI

- 6-1/2 X 4-1/4 inch rectangular, marked Type 2QA or 2A1

- 2000 X 142mm rectangular, marked Type 2B or 2B1

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 51, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012; Volume 32, Issue 24, eff. October 3, 2016; Volume 35, Issue 25, eff. September 1, 2019.

19VAC30-70-520. Rear lamps: tail lamp; license plate lamps; and rear lamp combinations.

A. Inspect for and reject if:

1. Vehicle is not equipped with a rear (tail lamp) or rear lamp combination of an approved type and the light or light assembly does not work as approved.

2. The vehicle is equipped with more than one rear lamp, if all are not in operating condition.

3. The vehicle is not equipped with a license plate lamp that emits a white light. The license plate lamp may be a separate lamp or part of a combination rear lamp. (A road tractor or tractor-truck that does not have a rear license plate is not required to have a license plate lamp.)

4. Lens for license plate lamp is not illuminated by a license plate lamp that emits a white light.

5. Lens on rear lamps, or lens area in combination rear lamps (tail lamps) are not red. LED (light-emitting diode) lights with a clear lens are acceptable. Vehicles equipped with a multiple LED light (not filament-burning bulbs) will pass inspection if more than 50% of the diode lights are burning.

6. Lens has piece broken from it or does not fit properly. The lens may have one or more cracks provided an off-color light does not project through the cracks.

NOTE: Taping or gluing cracks or pieces is not allowed.

7. Filament in all rear (tail) lamps does not burn when headlamp switch is turned on to any position, or if lamps do not provide a red light visible to the rear through an approved red lens as annotated in subdivision 1 of this subsection.

8. Rear (tail) lamp is not mounted near extreme rear of vehicle. Dump trucks and other specially constructed vehicles may mount the rear lamp at a point other than on the extreme rear, provided such rear lamp is clearly visible from the rear, and further provided that a red reflector of an approved type is mounted on the extreme rear. In unusual cases, the rear lamp may be mounted on the cab. Reject if the lamp is hidden by a bolster or other part of the body or frame, is not mounted securely, or if the lamp does not make a good electrical contact.

9. Wiring or electrical connections are defective or filaments do not burn.

10. Any vehicle has unapproved lens or plastic covers, any other materials that are not original equipment or any colored material placed on or in front of rear lamps, tail lamps, license plate lamps or rear lamp combinations.

B. Every trailer shall carry at the rear, two red lights of a type approved by the superintendent.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 52, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 32, Issue 24, eff. October 3, 2016; Volume 35, Issue 25, eff. September 1, 2019.

19VAC30-70-530. Auxiliary lamps: backup; cornering; driving; fog; spot and warning.

For auxiliary lamps on vehicles over 10,000 pounds, refer to 19VAC30-70-160 as the same requirements apply.

NOTE: Do not reject tractor trucks equipped with cargo lights of an approved type (SAE-G) that are mounted on the rear of the tractor cab and wired through an independent switch used to illuminate brake connectors and fifth-wheels for night time hook-ups.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 53, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 12, Issue 21, eff. August 7, 1996; Volume 17, Issue 15, eff. May 9, 2001; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012; Volume 32, Issue 24, eff. October 3, 2016; Volume 35, Issue 25, eff. September 1, 2019; Volume 40, Issue 10, eff. February 1, 2024.

19VAC30-70-540. Parking lamps.

Parking lamps are not required. However, if installed they must operate and be inspected. Parking lamps may burn in conjunction with the headlamps.

Inspect for and reject if:

1. Lamps are not of an approved type (DOT or SAE-P) or a lamp has been altered.

2. Parking lamps have other than clear or amber lenses showing to the front. If the lens is clear, then the bulb shall be amber.

3. Parking lamps do not burn with the rear lamps.

4. If lens has a piece broken from it. Lens may have one or more cracks provided no off-color light projects through the crack or cracks.

5. Wiring or electrical connections are defective or filaments do not burn.

6. Any vehicle has unapproved lens or plastic covers, any other materials which are not original equipment or any colored material placed on or in front of parking lamps.

NOTE. LED (light-emitting diode) lights with a clear lens are acceptable if of an approved type. For those vehicles that are equipped with a multiple LED light (not filament-burning bulbs), they will pass inspection if more than 50% of the diode lights are burning.

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 54, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 32, Issue 24, eff. October 3, 2016.

19VAC30-70-550. Clearance lamps, side marker lamps, and reflectors (under 26,000 pounds GVWR).

Inspect for and reject if:

1. Any motor vehicle, trailer, semitrailer or other vehicle is not equipped with clearance lamps if the vehicle is over seven feet wide or if any portion extends four inches or more outside the front fender line.

When a motor vehicle with a trailer attached is presented, the combination may be considered as one unit in meeting this requirement. If presented separately, the individual unit must meet these requirements except that any tractor-truck need not be equipped with rear red dimension or marker lamps.

2. Lamps or reflectors are not of an approved type or a lamp has been altered; any wires are exposed; unapproved lenses or plastic covers; or any other materials that are not original equipment or any colored material placed on or in front of lamps or reflectors.

EXCEPTION: A law-enforcement special weapons and tactics (SWAT) or tactical armored vehicle, designed and manufactured exclusively for SWAT missions, may apply protective bars in front of the clearance lamps, side marker lamps, and reflectors when designed and installed by the manufacturer.

Retro-reflective surfaces. Retro-reflective surfaces other than required reflectors may be used, provided (see diagram):

a. Designs do not resemble traffic control signs, lights, or devices, except that straight edge striping resembling a barricade pattern may be used.

b. Designs do not tend to distort the length or width of the motor vehicle.

c. Such surfaces shall be at least three inches from any required lamp or reflector unless of the same color as such lamp or reflector.

d. No red color shall be used on the front of any motor vehicle, except for display of markings or placards required by law.

3. Lenses or lamps on the front are not amber and lenses on lamps on the rear are not red or if a lens has a piece broken from it. A lens may have one or more cracks provided an off-color light does not project through the crack or cracks.

4. Wiring or electrical connections are defective or all filaments do not burn.

NOTE: Vehicles equipped with a multiple LED (light-emitting diode) light (not filament-burning bulbs) will pass inspection if more than 50% of the diode lights are burning.

5. Two amber lamps are not mounted on the front and two red lamps on the rear, so as to indicate the extreme width of the body, and as high on the permanent body as practical, except that approved 180 degree lamps with yellow or amber lens may be mounted on the side of the vehicle at or as near the front as possible, or if the front is not the widest portion, the lamps may be installed on the side and as near that point as possible.

And with the further exception that 180 degree lamps with red lens may be mounted on the side of the vehicle at or as near the rear as possible or if the rear is not the widest portion of the vehicle, the lamps may be installed on the side as near that point as possible.

NOTE: Any vehicle equipped with three red identification lamps with the lamp centers spaced not less than six inches or more than 12 inches apart and installed as close as practicable to the top of the vehicle and as close as practicable to the vertical centerline of the vehicle may have the rear dimension or marker lamps required by subdivision 5 of this section mounted at any height but indicate as nearly as practicable the extreme width of the vehicle.

NOTE: Dump trucks with a high lift body, concrete mixer trucks and other specially constructed vehicles may be equipped with the required clearance lamps not mounted on the extreme rear, provided such red lamps are clearly visible from the rear and provided further that two red reflectors of an approved type are mounted on the extreme rear. In unusual cases the rear lamp may be mounted on the cab and another red reflex reflector placed on the extreme rear.

NOTE: In addition to the required clearance lamps showing to the front and to the rear, a vehicle may be equipped with side marker lamps on the side of the vehicle. When such an installation is used, all of the side marker lamps on the side except the one at or near the rear must have an amber lens. The side marker lamps on the side at or near the rear must have a red lens.

6. Any vehicle covered by subdivision 1 of this section, except school buses, is not equipped with amber reflectors on the sides as near the front as practical, and red reflectors on the rear. The reflectors must be at least 15 inches and not more than 60 inches from the ground. No reflector can have a piece broken from its reflective surface, but may have one or more cracks.

7. Any combination of vehicles whose actual length exceeds 35 feet if the vehicle is not equipped with reflex reflectors of a type approved by the superintendent and mounted on the widest part of the towed vehicle so as to be visible from the front and sides of the vehicle. No reflector can have a piece broken from its reflective surface, but may have one or more cracks.

8. Any passenger vehicle is equipped with clearance lamps, unless such lamps are used to mark the extreme width of the vehicle or used as taxicab identification, or used as supplemental turn signals. (See 19VAC30-70-190 B.)

NOTE: Vehicles so constructed as to make compliance with the requirements of subdivisions 1, 5, 7, and 9 of this section impractical, will be equipped with clearance lamps and reflectors at the most practical location to provide maximum visibility.

9. Any vehicle is not equipped with: two front side marker lights (amber), two rear side marker lights (red), and two rear reflectors (red).

|

|

|

| ||

|

|

|

| ||

|

|

|

| ||

|

|

|

| ||

|

|

|

| ||

|

|

|

| ||

|

| ||||

Statutory Authority

§ 46.2-1165 of the Code of Virginia.

Historical Notes

Derived from VR545-01-07 § 55, eff. May 1, 1990; amended, Virginia Register Volume 10, Issue 8, eff. February 9, 1994; Volume 15, Issue 2, eff. November 11, 1998; Volume 21, Issue 4, eff. September 22, 2004; Volume 24, Issue 8, eff. March 1, 2008; Volume 28, Issue 24, eff. August 1, 2012; Volume 32, Issue 24, eff. October 3, 2016; Errata, 32:26 VA.R. 3588 August 22, 2016; amended, Virginia Register Volume 35, Issue 25, eff. September 1, 2019.