Part II. Emission Standards

Article 1

Visible Emissions and Fugitive Dust/Emissions (Rule 4‑1)

9VAC5-40-60. Applicability and designation of affected facility.

Article 1

Visible Emissions and Fugitive Dust/Emissions (Rule 4‑1)

A. The affected facilities to which the provisions of this article apply are the following:

1. Each source of visible emissions; and

2. Each source of fugitive dust/emissions.

B. The provisions of this article apply throughout the Commonwealth of Virginia.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0101, eff. January 1, 1985.

9VAC5-40-70. Definitions.

A. For the purpose of these regulations and subsequent amendments or any orders issued by the board, the words and terms shall have the meanings given them in subsection C of this section.

B. As used in this article, all terms not defined here shall have the meanings given them in 9VAC5 Chapter 10 (9VAC5-10-10 et seq.), unless otherwise required by context.

C. Terms defined.

"Fugitive dust" means particulate matter composed of soil or other materials, or both, of natural origin. Fugitive dust may include emissions from haul roads, wind erosion of exposed surfaces and storage piles and other activities in which the material is either removed, stored, transported or redistributed.

"Fugitive emissions" means emissions which are generated by industrial or other activities and which do not pass through a stack, chimney, vent or other functionally equivalent opening, but which may escape from openings (such as windows, doors, ill-fitting closures or poorly maintained equipment) or material handling equipment.

"Opacity" means the degree to which emissions reduce the transmission of light and obscure the view of an object in the background, expressed as a percentage.

"Six-minute period" means any one of the 10 equal parts of one hour or a one-hour period, as may be applicable.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0102, eff. January 1, 1985.

9VAC5-40-80. Standard for visible emissions.

Unless specified otherwise in this part, no owner or other person shall cause or permit to be discharged into the atmosphere from any affected facility any visible emissions which exhibit greater than 20% opacity, except for one six-minute period in any one hour of not more than 60% opacity. Failure to meet the requirements of this section because of the presence of water vapor shall not be a violation of this section.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120‑04‑0103, eff. January 1, 1985.

9VAC5-40-90. Standard for fugitive dust/emissions.

No owner or other person shall cause or permit any materials or property to be handled, transported, stored, used, constructed, altered, repaired or demolished without taking reasonable precautions to prevent particulate matter from becoming airborne. Such reasonable precautions may include, but are not limited to, the following:

1. Use, where possible, of water or chemicals for control of dust in the demolition of existing buildings or structures, construction operations, the grading of roads or the clearing of land.

2. Application of asphalt, water, or suitable chemicals on dirt roads, materials stockpiles and other surfaces which may create airborne dust; the paving of roadways and maintaining them in a clean condition.

3. Installation and use of hoods, fans and fabric filters to enclose and vent the handling of dusty materials. Adequate containment methods shall be employed during sandblasting or other similar operations.

4. Open equipment for conveying or transporting materials likely to create objectionable air pollution when airborne shall be covered or treated in an equally effective manner at all times when in motion.

5. The prompt removal of spilled or tracked dirt or other materials from paved streets and of dried sediments resulting from soil erosion.

Statutory Authority

§ 10.1-1308 of the Code of Virginia and §§ 110, 111, 123, 129, 171, 172 and 182 of the Clean Air Act; 40 CFR Parts 51 and 60.

Historical Notes

Derived from VR120-04-0104, eff. January 1, 1985; amended, Virginia Register Volume 19, Issue 6, eff. February 1, 2003.

9VAC5-40-100. Monitoring.

A. Unless otherwise approved by the board, all continuous monitoring systems required by this article shall be installed, calibrated, maintained and operated in accordance with applicable requirements in 9VAC5-40-40 and 9VAC5-40-41.

B. Each owner required to install a continuous monitoring system shall provide notifications and reports and maintain records and monitoring results in accordance with the requirements of 9VAC5-40-50.

C. In cases where the requirements of 9VAC5-40-40 and 9VAC5-40-41 are not appropriate for a particular source type, the owner shall comply with other procedures acceptable to the board.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0105, eff. January 1, 1985.

9VAC5-40-110. Test methods and procedures.

The provisions of 9VAC5-40-20 A 2 apply to determine compliance with the standard prescribed in 9VAC5-40-80.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0106, eff. January 1, 1985.

9VAC5-40-120. Waivers.

A. A waiver from the opacity emission limitation in 9VAC5-40-80 may be granted by the director, provided that a technical decision is reached that the plume opacity observations made in accordance with 9VAC5-40-20 and 9VAC5-40-110 are not representative of the pollutant loading of the plume.

B. Upon granting the above waiver, the director shall require one or more alternate source surveillance methods, which may include, but are not limited to, the following:

1. Requiring the owner to install, calibrate, maintain and operate systems for continuously monitoring and recording emissions of specified pollutants in accordance with 9VAC5-40-40 and 9VAC5-40-100.

2. Requiring the owner to conduct, at specified intervals, emission tests for measuring emissions of specified pollutants in accordance with 9VAC5-40-30.

3. Establishing an opacity emission limitation for the facility based on a correlation between tests of visible and other specified pollutant emissions.

C. The waiver may be granted for an indefinite period of time; however, approval may be withdrawn by the director:

1. For failure to adhere to any terms or conditions of the waiver;

2. If the affected facility is found to be in violation of any applicable emission standard; or

3. For failure to conduct or adhere to any alternate source surveillance method required for waiver approval.

Statutory Authority

§ 10.1-1308 of the Code of Virginia and §§ 110, 111, 123, 129, 171, 172 and 182 of the Clean Air Act; 40 CFR Parts 51 and 60.

Historical Notes

Derived from VR120-04-0107, eff. January 1, 1985; amended, Virginia Register Volume 19, Issue 6, eff. February 1, 2003.

Article 2

Emission Standards for Odor (Rule 4‑2)

9VAC5-40-130. Applicability and designation of affected facility.

Article 2

Emission Standards for Odor (Rule 4‑2)

A. Except as provided in subsection C of this section, the affected facility to which the provisions of this article apply is each facility that emits odor.

B. The provisions of this article apply throughout the Commonwealth of Virginia.

C. The provisions of this article do not apply to accidental or other infrequent emissions of odors.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120‑04‑0201, eff. January 1, 1985.

9VAC5-40-140. Standard for odor.

No owner or other person shall cause or permit to be discharged into the atmosphere from any affected facility any emissions which cause an odor objectionable to individuals of ordinary sensibility.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0203, eff. January 1, 1985.

9VAC5-40-150. Determination of violation.

A. The determination of objectionable odor shall be made after a thorough review of all data or evidence relating to the situation which may be obtained by an investigation directed by the board. As a part of the investigation, the board, at its discretion, may hold a public hearing in accordance with 9VAC5-20-40 A 1 to hear complaints. The investigation may also include use of an odor panel survey and other methods approved by the board, or both.

B. Upon determination that an odor violates 9VAC5-40-140 the owner shall use such measures as approved by the board for the economically and technologically feasible control of odorous emissions.

Article 3

Emission Standards for Toxic Pollutants (Rule 4-3) [Repealed]

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0204, eff. January 1, 1985.

Article 3

Emission Standards for Toxic Pollutants (Rule 4-3) [Repealed]

9VAC5-40-160. (Repealed.)

Article 3

Emission Standards for Toxic Pollutants (Rule 4-3) [Repealed]

Historical Notes

Derived from VR120-04-0301, eff. October 15, 1991; repealed, Virginia Register Volume 18, Issue 14, eff. May 1, 2002.

Article 4

Emission Standards for General Process Operations (Rule 4-4)

9VAC5-40-240. Applicability and designation of affected facility.

Article 4

Emission Standards for General Process Operations (Rule 4-4)

A. Except as provided in subsections C and D of this section, the affected facility to which the provisions of this article apply is each process operation, each process gas stream and each combustion installation.

B. The provisions of this article apply throughout the Commonwealth of Virginia.

C. Exempted from the provisions of this article are the following:

1. Process operations with a process weight rate capacity less than 100 pounds per hour.

2. Any combustion unit using solid fuel with a maximum heat input of less than 350,000 Btu per hour.

3. Any combustion unit using liquid fuel with a maximum heat input of less than 1,000,000 Btu per hour.

4. Any combustion unit using gaseous fuel with a maximum heat input of less than 10,000,000 Btu per hour.

D. The provisions of this article do not apply to a particular pollutant from an affected facility if the affected facility is subject to other emission standards in this chapter covering the same pollutant.

Statutory Authority

§ 10.1-1308 of the Code of Virginia, §§ 110 and 182 of the Clean Air Act, and 40 CFR Part 51.

Historical Notes

Derived from VR120-04-0401, eff. January 1, 1985; amended, Virginia Register Volume 12, Issue 11, eff. April 1, 1996; Volume 18, Issue 4, eff. January 1, 2002; Volume 20, Issue 12, eff. March 24, 2004.

9VAC5-40-250. Definitions.

A. For the purpose of the Regulations for the Control and Abatement of Air Pollution and subsequent amendments or any orders issued by the board, the words or terms shall have the meanings given them in subsection C of this section.

B. As used in this article, all terms not defined herein shall have the meanings given them in 9VAC5 Chapter 10 (9VAC5-10-10 et seq.), unless otherwise required by context.

C. Terms defined.

"Combustion installation" means all combustion units within a stationary source in operation prior to October 5, 1979.

"Combustion unit" means any type of stationary equipment in which solid, liquid or gaseous fuels and refuse are burned, including, but not limited to, furnaces, ovens, and kilns.

"Heat input" means the total gross calorific value of all fuels burned.

"Manufacturing operation" means any process operation or combination of physically connected dissimilar process operations which is operated to effect physical or chemical changes or both in an article.

"Materials handling equipment" means any equipment used as a part of a process operation or combination of process operations which does not effect a physical or chemical change in the material or in an article, such as, but not limited to, conveyors, elevators, feeders or weighers.

"Physically connected" means any combination of process operations connected by materials handling equipment and designed for simultaneous complementary operation.

"Process operation" means any method, form, action, operation or treatment of manufacturing or processing, including any storage or handling of materials or products before, during or after manufacturing or processing.

"Process unit" means any step in a manufacturing or process operation which results in the emission of pollutants to the atmosphere.

"Process weight" means total weight of all materials introduced into any process unit which may cause any emission of pollutants. Process weight includes solid fuels charged, but does not include liquid and gaseous fuels charged or combustion air for all fuels.

"Process weight rate" means a rate established as follows:

a. For continuous or long-run steady-state process operations, the total process weight for the entire period of continuous operation or for a typical portion of it, divided by the number of hours of such period or portion of it.

b. For cyclical or batch process operations, the total weight for a period that covers a complete operation or an integral number of cycles, divided by the hours of actual process operation during such a period.

"Rated capacity" means, the capacity as stipulated in the purchase contract for the condition of 100% load, or such other capacities as mutually agreed to by the board and owner using good engineering judgment.

"Total capacity" means with reference to a combustion installation, the sum of the rated capacities (expressed as heat input) of all units of the installation which must be operated simultaneously under conditions of 100% use load.

Statutory Authority

§ 10.1-1308 of the Code of Virginia; §§ 110, 111, 123, 129, 171, 172 and 182 of the Clean Air Act; 40 CFR Parts 51 and 60.

Historical Notes

Derived from VR120-04-0402, eff. July 1, 1991; amended, Virginia Register Volume 12, Issue 11, eff. April 1, 1996; Volume 18, Issue 4, eff. January 1, 2002; Volume 23, Issue 5, eff. December 15, 2006.

9VAC5-40-260. Standard for particulate matter (AQCR 1-6).

A. No owner or other person shall cause or permit to be discharged into the atmosphere from any process unit any particulate emissions in excess of the limits in Table 4-4A.

| Process Weight Rate | Maximum Allowable Emission Rate | |

| Lb/Hr | Tons/Hr | Lb/Hr |

| 100 | 0.05 | 0.551 |

| 200 | 0.10 | 0.877 |

| 400 | 0.20 | 1.40 |

| 600 | 0.30 | 1.83 |

| 800 | 0.40 | 2.22 |

| 1000 | 0.50 | 2.58 |

| 1500 | 0.75 | 3.38 |

| 2000 | 1.00 | 4.10 |

| 2500 | 1.25 | 4.76 |

| 3000 | 1.50 | 5.38 |

| 3500 | 1.75 | 5.96 |

| 4000 | 2.00 | 6.52 |

| 5000 | 2.50 | 7.58 |

| 6000 | 3.00 | 8.56 |

| 7000 | 3.50 | 9.49 |

| 8000 | 4.00 | 10.4 |

| 9000 | 4.50 | 11.2 |

| 10000 | 5.00 | 12.0 |

| 12000 | 6.00 | 13.6 |

| 16000 | 8.00 | 16.5 |

| 18000 | 9.00 | 17.9 |

| 20000 | 10.00 | 19.2 |

| 30000 | 15.00 | 25.2 |

| 40000 | 20.00 | 30.5 |

| 50000 | 25.00 | 35.4 |

| 60000 | 30.00 | 40.0 |

| 70000 | 35.00 | 41.3 |

| 80000 | 40.00 | 42.5 |

| 90000 | 45.00 | 43.6 |

| 100000 | 50.00 | 44.6 |

| 120000 | 60.00 | 46.3 |

| 140000 | 70.00 | 47.8 |

| 160000 | 80.00 | 49.1 |

| 200000 | 100.00 | 51.3 |

| 1000000 | 500.00 | 69.0 |

| 2000000 | 1000.00 | 77.6 |

| 6000000 | 3000.00 | 92.7 |

B. Except as provided in subsections C and D of this section, interpretation of the emission standard in subsection A of this section shall be in accordance with 9VAC5-40-22.

C. Interpolation of the data in Table 4-4A for process weight rates up to 60,000 lb/hr shall be accomplished by use of the following equation:

E = 4.10 P0.67

where:

E = emission rate in lb/hr.

P = process weight rate in tons/hr.

D. Interpolation and extrapolation of the data for process weight rates in excess of 60,000 lb/hr shall be accomplished by use of the following equation:

E = 55.0 P0.11 - 40

where:

E = emission rate in lb/hr.

P = process weight rate in tons/hr.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0403, eff. January 1, 1985.

9VAC5-40-270. Standard for particulate matter (AQCR 7).

A. Noncombustion process operations. No owner or other person shall cause or permit to be discharged into the atmosphere from any process unit any particulate emissions in excess of the limits in Table 4-4B.

| TABLE 4-4B | ||

| Process Weight Rate | Maximum Allowable Emission Rate | |

| Lb/Hr | Tons/Hr | Lb/Hr |

| 100 | 0.050 | 0.46 |

| 150 | 0.075 | 0.66 |

| 200 | 0.100 | 0.85 |

| 250 | 0.125 | 1.03 |

| 300 | 0.150 | 1.20 |

| 350 | 0.175 | 1.35 |

| 400 | 0.200 | 1.50 |

| 450 | 0.225 | 1.63 |

| 500 | 0.250 | 1.77 |

| 550 | 0.275 | 1.85 |

| 600 | 0.300 | 2.01 |

| 650 | 0.325 | 2.12 |

| 700 | 0.350 | 2.24 |

| 750 | 0.375 | 2.34 |

| 800 | 0.400 | 2.43 |

| 850 | 0.425 | 2.53 |

| 900 | 0.450 | 2.62 |

| 950 | 0.475 | 2.72 |

| 1000 | 0.500 | 2.80 |

| 1100 | 0.55 | 2.97 |

| 1200 | 0.60 | 3.12 |

| 1300 | 0.65 | 3.26 |

| 1400 | 0.70 | 3.40 |

| 1500 | 0.75 | 3.54 |

| 1600 | 0.80 | 3.66 |

| 1700 | 0.85 | 3.79 |

| 1800 | 0.90 | 3.91 |

| 1900 | 0.95 | 4.03 |

| 2000 | 1.00 | 4.14 |

| 2100 | 1.05 | 4.24 |

| 2200 | 1.10 | 4.34 |

| 2300 | 1.15 | 4.44 |

| 2400 | 1.20 | 4.55 |

| 2500 | 1.25 | 4.64 |

| 2600 | 1.30 | 4.74 |

| 2700 | 1.35 | 4.84 |

| 2800 | 1.40 | 4.92 |

| 2900 | 1.45 | 5.02 |

| 3000 | 1.50 | 5.10 |

| 3100 | 1.55 | 5.18 |

| 3200 | 1.60 | 5.27 |

| 3300 | 1.65 | 5.36 |

| 3400 | 1.70 | 5.44 |

| 3500 | 1.75 | 5.52 |

| 3600 | 1.80 | 5.61 |

| 3700 | 1.85 | 5.69 |

| 3800 | 1.90 | 5.77 |

| 3900 | 1.95 | 5.85 |

| 4000 | 2.00 | 5.93 |

| 4100 | 2.05 | 6.01 |

| 4200 | 2.10 | 6.08 |

| 4300 | 2.15 | 6.15 |

| 4400 | 2.20 | 6.22 |

| 4500 | 2.25 | 6.30 |

| 4600 | 2.30 | 6.37 |

| 4700 | 2.35 | 6.45 |

| 4800 | 2.40 | 6.52 |

| 4900 | 2.45 | 6.60 |

| 5000 | 2.50 | 6.67 |

| 5500 | 2.75 | 7.03 |

| 6000 | 3.00 | 7.37 |

| 6500 | 3.25 | 7.71 |

| 7000 | 3.50 | 8.05 |

| 7500 | 3.75 | 8.39 |

| 8000 | 4.00 | 8.71 |

| 8500 | 4.25 | 9.03 |

| 9000 | 4.50 | 9.36 |

| 9500 | 4.75 | 9.67 |

| 10000 | 5.00 | 10.00 |

| 11000 | 5.50 | 10.63 |

| 12000 | 6.00 | 11.28 |

| 13000 | 6.50 | 11.89 |

| 14000 | 7.00 | 12.50 |

| 15000 | 7.50 | 13.13 |

| 16000 | 8.00 | 13.74 |

| 17000 | 8.50 | 14.36 |

| 18000 | 9.00 | 14.97 |

| 19000 | 9.50 | 15.58 |

| 20000 | 10.00 | 16.19 |

| 30000 | 15.00 | 22.22 |

| 40000 | 20.00 | 28.30 |

| 50000 | 25.00 | 34.30 |

| 60000 or more | 30.00 or more | 40.00 |

B. Combustion installations. Interpretation of the emission standard in subsection A of this section shall be in accordance with 9VAC5-40-22.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0404, eff. January 1, 1985.

9VAC5-40-280. Standard for sulfur dioxide.

A. Noncombustion process operations. No owner or other person shall cause or permit to be discharged into the atmosphere from any process operation any sulfur dioxide emissions in excess of an in-stack concentration of 2000 ppm by volume.

B. Combustion installations.

1. No owner or other person shall cause or permit to be discharged into the atmosphere from any combustion installation any sulfur dioxide emissions in excess of the following limits:

a. S = 2.64K (AQCR 1 through 6)

b. S = 1.06K (for liquid or gaseous fuels - AQCR 7)

c. S = 1.52K (for solid fuels - AQCR 7)

where:

S = allowable emission of sulfur dioxide

expressed in lbs/hr.

K = actual heat input at total capacity expressed in Btu X 106 per hour.

2. Where there is more than one unit in a combustion installation and where the installation can be shown, to the satisfaction of the board, to be in compliance when the installation is operating at total capacity, the installation will be deemed to still be in compliance when the installation is operated at reduced load or one or more units are shut down for maintenance or repair, provided that the same type of fuel with the same sulfur content, or an equivalent, is continued in use.

3. For installations in AQCR 7 at which different fossil fuels are burned simultaneously, whether in the same or different units, the allowable emissions shall be determined by proration using the following formula:

|

| PS = K | X(1.06) + Y(1.52) |

|

| X + Y |

where:

PS = prorated allowable emissions of sulfur dioxide expressed in lb/hr.

X = percentage of actual heat input at total capacity derived from liquid or gaseous fuel.

Y = percentage of actual heat input at total capacity derived from solid fuels.

K = actual heat input at total capacity expressed in Btu X 106 per hour.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0405, eff. January 1, 1985.

9VAC5-40-290. Standard for hydrogen sulfide.

No owner or other person shall cause or permit to be discharged into the atmosphere from any process gas stream any hydrogen sulfide emissions in excess of a concentration greater than 15 grains per 100 cubic feet of gas without burning or removing H2S in excess of this concentration, provided that SO2 emissions in the burning operation meet the requirements of 9VAC5-40-280 A.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0406, eff. January 1, 1985.

9VAC5-40-300. (Repealed.)

Historical Notes

Derived from VR120-04-0407, eff. July 1, 1991, VR120-04-0408, eff. July 1, 1991 or Virginia Register Volume 13, Issue 18, eff. July 1, 1997; amended, Virginia Register Volume 9, Issue 5, eff. January 1, 1993; Volume 12, Issue 11, eff. April 1, 1996; Volume 18, Issue 4, eff. January 1, 2002; Volume 19, Issue 17, eff. June 4, 2003; Volume 20, Issue 12, eff. March 24, 2004; Errata 20:15 VA.R. 1498-1504 April 5, 2004; amended, Virginia Register Volume 22, Issue 26, eff. October 4, 2006; repealed, Virginia Register Volume 23, Issue 5, eff. December 15, 2006.

9VAC5-40-320. Standard for visible emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0409, eff. January 1, 1985.

9VAC5-40-330. Standard for fugitive dust/emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0410, eff. January 1, 1985.

9VAC5-40-340. Standard for odor.

The provisions of Article 2 (9VAC5-40-130 et seq.) of this chapter (Emission Standards for Odor, Rule 4-2) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0411, eff. January 1, 1985.

9VAC5-40-350. Standard for toxic pollutants.

The provisions of Article 3 (9VAC5-40-160 et seq.) of this chapter (Emission Standards for Toxic Pollutants, Rule 4-3) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0412, eff. January 1, 1985.

9VAC5-40-360. Compliance.

The provisions of 9VAC5-40-20 (Compliance) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0413, eff. January 1, 1985.

9VAC5-40-370. Test methods and procedures.

The provisions of 9VAC5-40-30 (Emission Testing) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0414, eff. January 1, 1985.

9VAC5-40-380. Monitoring.

The provisions of 9VAC5-40-40 (Monitoring) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0415, eff. January 1, 1985.

9VAC5-40-390. Notification, records and reporting.

The provisions of 9VAC5-40-50 (Notification, Records and Reporting) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0416, eff. January 1, 1985.

9VAC5-40-400. Registration.

The provisions of 9VAC5-20-160 (Registration) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0417, eff. January 1, 1985.

9VAC5-40-410. Facility and control equipment maintenance or malfunction.

The provisions of 9VAC5-20-180 (Facility and Control Equipment Maintenance or Malfunction) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0418, eff. January 1, 1985.

9VAC5-40-420. Permits.

A permit may be required prior to beginning any of the activities specified below and the provisions of 9VAC5 Chapter 50 (9VAC5-50-10 et seq.) and 9VAC5 Chapter 80 (9VAC5-80-10 et seq.) may apply. Owners contemplating such action should contact the appropriate regional office for guidance.

1. Construction of a facility.

2. Reconstruction (replacement of more than half) of a facility.

3. Modification (any physical change to equipment) of a facility.

4. Relocation of a facility.

5. Reactivation (restart-up) of a facility.

6. Operation of a facility.

Statutory Authority

§ 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0419, eff. January 1, 1985; amended, Virginia Register Volume 12, Issue 11, eff. April 1, 1996.

Article 5

Emission Standards for Synthesized Pharmaceutical Products Manufacturing Operations (Rule 4-5)

9VAC5-40-430. Applicability and designation of affected facility.

Article 5

Emission Standards for Synthesized Pharmaceutical Products Manufacturing Operations (Rule 4-5)

A. The affected facility to which the provisions of this article apply is each process unit or operation.

B. The provisions of this article apply only to sources of volatile organic compounds in volatile organic compound emissions control areas designated in 9VAC5-20-206.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0501, eff. July 1, 1991.

9VAC5-40-440. Definitions.

A. For the purpose of these regulations and subsequent amendments or any orders issued by the board, the words or terms shall have the meanings given them in subsection C of this section.

B. As used in this article, all terms not defined here shall have the meanings given them in 9VAC5 Chapter 10 (9VAC5-10-10 et seq.), unless otherwise required by context.

C. Terms defined.

"Condenser" means a device which removes condensable vapors by a reduction in the temperature of the captured gases.

"Production equipment exhaust system" means a device for collecting and directing out of the work area volatile organic compound fugitive emissions from reactor openings, centrifuge openings and other vessel openings for the purpose of protecting workers from excessive volatile organic compound exposure.

"Reactor" means a vessel designed to carry out chemical reactions under controlled conditions.

"Synthesized pharmaceutical products manufacturing" means manufacture of pharmaceutical products by chemical synthesis.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0502, eff. January 1, 1985.

9VAC5-40-450. Standard for volatile organic compounds.

A. Reactors, distillation operations, crystallizers, centrifuges and vacuum dryers.

1. No owner or other person shall use or permit the use of any reactor, distillation operation, crystallizer, centrifuge or vacuum dryer process unit unless such unit is equipped with a vapor control system that will remove, destroy or prevent the discharge into the atmosphere of at least 90% by weight of volatile organic compound emissions.

2. Achievement of the emission standard in subsection A 1 of this section by use of methods in 9VAC5-40-460 A and E will be acceptable to the board.

B. Air dryers and production equipment exhaust systems.

1. No owner or other person shall use or permit the use of any air dryer or production equipment exhaust system process unit unless such unit is equipped with a vapor control system that will remove, destroy or prevent the discharge into the atmosphere of at least 90% by weight of volatile organic compound emissions.

2. Achievement of the emission standard in subsection B 1 of this section by use of methods in 9VAC5-40-460 B and E will be acceptable to the board.

C. Filling of storage tanks.

1. No owner or other person shall use or permit the use of any stationary storage tank of more than 2,000 gallons capacity for storage of any volatile organic compound unless such tank is equipped with a vapor control system that will remove, destroy or prevent the discharge into the atmosphere of at least 90% by weight of volatile organic compound emissions during the filling of such tank.

2. Achievement of the emission standard in subsection C 1 of this section by use of the methods in 9VAC5-40-460 C and E will be acceptable to the board.

3. The provisions of subsection C of this section shall not be applicable to facilities using volatile organic compounds with a vapor pressure less than 4.1 pounds per square inch absolute at 68°F.

D. Volatile organic compound storage.

1. No owner or other person shall use or permit the use of any tank for storage of volatile organic compounds, unless such tank is equipped with a vapor control system which will remove, destroy or prevent the discharge into the atmosphere of at least 90% by weight of volatile organic compound emissions.

2. Achievement of the emission standard in subsection D 1 of this section by use of control methods in 9VAC5-40-460 D and E will be acceptable to the board.

3. The provisions of subsection D of this section shall not be applicable to facilities using volatile organic compounds with a vapor pressure less than 1.5 pounds per square inch absolute at 68°F.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0503, eff. July 1, 1991.

9VAC5-40-460. Control technology guidelines.

A. Reactors, distillation operations, crystallizers, centrifuges and vacuum dryers. The control system should consist of one of the following:

1. Surface condensation system with an outlet temperature not greater than:

a. -13°F when condensing volatile organic compounds of vapor pressure greater than 5.8 psi;

b. 5°F when condensing volatile organic compounds of vapor pressure greater than 2.9 psi;

c. 32°F when condensing volatile organic compounds of vapor pressure greater than 1.5 psi;

d. 50°F when condensing volatile organic compounds of vapor pressure greater than 1.0 psi; or

e. 77°F when condensing volatile organic compounds of vapor pressure greater than 0.5 psi.

2. Any system of equal or greater control efficiency when compared to the standard in 9VAC5-40-450 A 1, provided such system is approved by the board.

B. Air dryers and production equipment exhaust systems. The control system should consist of one of the following:

1. Condensation system.

2. Wet scrubbing system.

3. Carbon adsorption system.

4. Incineration.

5. Any system of equal or greater control efficiency when compared to the standard in 9VAC5-40-450 B 1, provided such system is approved by the board.

C. Filling of storage tanks. The tank should be a pressure tank maintaining working pressure sufficient at all times to prevent vapor loss to the atmosphere, or be designed and equipped with one of the following vapor control systems:

1. A submerged fill pipe.

2. A vapor control system with the vapor recovery portion consisting of one of the following:

a. A vapor tight return line from the storage container to the tank truck which shall be connected before liquids are transferred into the container.

b. Any adsorption system or condensation system.

3. A vapor control system with the vapor balance portion meeting the following criteria:

a. There should be no leaks in the tank trucks' pressure vacuum relief valves and hatch covers, nor truck tanks, storage tanks and associated vapor return lines during loading or unloading operations.

b. The pressure relief valves on storage containers and tank trucks should be set to release at no less than 0.7 psi or the highest possible pressure in accordance with the following National Fire Prevention Association Standards: "Standard for Tank Vehicles for Flammable and Combustible Liquids," "Flammable and Combustible Liquids Code, "Code for Motor Fuel Dispensing Facilities and Repair Garages" (see 9VAC5-20-21).

c. Pressure in the vapor collection lines should not exceed tank truck pressure relief valve settings.

d. All loading and vapor lines should be equipped with fittings which make vapor tight connections and which close when disconnected.

4. Any system of equal or greater control efficiency when compared to the standard in 9VAC5-40-450 C 1, provided such system is approved by the board.

D. Volatile organic compound storage.

1. The tank should be a pressure tank maintaining working pressure sufficient at all times to prevent vapor loss to the atmosphere, or be designed and equipped with one of the following vapor control systems:

a. Use of pressure/vacuum conservation vent set at + or %68 .030 psi.

b. Vent condensation system.

c. Carbon adsorption system.

d. An internal floating roof resting on the surface of the liquid contents and equipped with a closure seal, or seals, to close the space between the roof edge and tank shell. All tank gauging and sampling devices should be vapor tight except when gauging or sampling is taking place.

e. Any system of equal or greater control efficiency when compared to the standard in 9VAC5-40-450 D 1, provided such system is approved by the board.

2. There should be no visible holes, tears or other openings in the seal or any seal fabric.

3. All openings, except stub drains, should be equipped with a cover, seal or lid. The cover, seal or lid should be in a closed position at all times except when the device is in actual use. Automatic bleeder vents should be closed at all times except when the roof is floated off or landed on the roof leg supports. Rim vents, if provided, should be set to open when the roof is being floated off the roof leg supports or at the manufacturer's recommended setting.

4. The exterior aboveground surfaces (exposed to sunlight) should be painted white, light pastels or light metallic and such exterior paint should be periodically maintained in good condition. Repainting may be performed during normal maintenance periods.

E. General.

1. All centrifuges containing volatile organic compounds, rotary vacuum filters processing liquids containing volatile organic compounds and any other filters having an exposed liquid surface where the liquid contains volatile organic compounds should be enclosed. This applies to liquids exerting a total volatile organic compound vapor pressure of 0.5 psi or more at 68°F.

2. All in-process tanks should have covers. Covers should be closed when possible.

3. For liquids containing volatile organic compounds, all leaks in which liquids can be observed to be running or dripping from vessels and equipment (for example: pumps, valves, flanges) should be repaired as soon as is practical.

Statutory Authority

§ 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0504, eff. July 1, 1991; amended, Virginia Register Volume 18, Issue 7, eff. February 1, 2002.

9VAC5-40-470. Standard for visible emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0505, eff. January 1, 1985.

9VAC5-40-480. Standard for fugitive dust/emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0506, eff. January 1, 1985.

9VAC5-40-490. Standard for odor.

The provisions of Article 2 (9VAC5-40-130 et seq.) of this chapter (Emission Standards for Odor, Rule 4-2) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0507, eff. January 1, 1985.

9VAC5-40-500. Standard for toxic pollutants.

The provisions of Article 3 (9VAC5-40-160 et seq.) of this chapter (Emission Standards for Toxic Pollutants, Rule 4-3) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0508, eff. January 1, 1985.

9VAC5-40-510. Compliance.

The provisions of 9VAC5-40-20 (Compliance) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0509, eff. January 1, 1985.

9VAC5-40-520. Test methods and procedures.

The provisions of 9VAC5-40-30 (Emission Testing) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0510, eff. January 1, 1985.

9VAC5-40-530. Monitoring.

The provisions of 9VAC5-40-40 (Monitoring) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0511, eff. January 1, 1985.

9VAC5-40-540. Notification, records and reporting.

The provisions of 9VAC5-40-50 (Notification, Records and Reporting) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0512, eff. January 1, 1985.

9VAC5-40-550. Registration.

The provisions of 9VAC5-20-160 (Registration) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0513, eff. January 1, 1985.

9VAC5-40-560. Facility and control equipment maintenance or malfunction.

The provisions of 9VAC5-20-180 (Facility and Control Equipment Maintenance or Malfunction) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0514, eff. January 1, 1985.

9VAC5-40-570. Permits.

A permit may be required prior to beginning any of the activities specified below and the provisions of 9VAC5 Chapter 50 (9VAC5-50-10 et seq.) and 9VAC5 Chapter 80 (9VAC5-80-10 et seq.) may apply. Owners contemplating such action should contact the appropriate regional office for guidance.

1. Construction of a facility.

2. Reconstruction (replacement of more than half) of a facility.

3. Modification (any physical change to equipment) of a facility.

4. Relocation of a facility.

5. Reactivation (restart-up) of a facility.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0515, eff. January 1, 1985.

Article 6

Emission Standards for Rubber Tire Manufacturing Operations (Rule 4-6)

9VAC5-40-580. Applicability and designation of affected facility.

Article 6

Emission Standards for Rubber Tire Manufacturing Operations (Rule 4-6)

A. The affected facility to which the provisions of this article apply is each process unit or operation.

B. The provisions of this article apply only to sources of volatile organic compounds in volatile organic compound emissions control areas designated in 9VAC5-20-206.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0601, eff. July 1, 1991.

9VAC5-40-590. Definitions.

A. For the purpose of these regulations and subsequent amendments or any orders issued by the board, the words or terms shall have the meanings given them in subsection C of this section.

B. As used in this article, all terms not defined here shall have the meanings given them in 9VAC5 Chapter 10 (9VAC5-10-10 et seq.), unless otherwise required by context.

C. Terms defined.

"Bead dipping" means the dipping of an assembled tire bead into a solvent based cement.

"Green tires" means assembled tires before molding and curing have occurred.

"Green tire spraying" means the spraying of green tires, both inside and outside, with release compounds which help remove air from the tire during molding and prevent the tire from sticking to the mold after curing.

"Pneumatic rubber tire manufacture" means the production of passenger car tires, light and medium truck tires, and other tires manufactured on assembly lines using automated equipment.

"Tread end cementing" means the application of a solvent based cement to the tire tread ends.

"Undertread cementing" means the application of a solvent based cement to the underside of a tire tread.

"Water based sprays" means release compounds, sprayed on the inside and outside of green tires, in which solids, water and emulsifiers have been substituted for all organic solvents.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0602, eff. January 1, 1985.

9VAC5-40-600. Standard for volatile organic compounds.

A. Undertread cementing.

1. No owner or other person shall use or permit the use of any undertread cementing process unit unless such unit is equipped with a vapor control system that will remove, destroy or prevent the discharge into the atmosphere of at least 85% by weight of volatile organic compound emissions.

2. Achievement of the emission standard in subsection A 1 of this section by use of methods in 9VAC5-40-610 A will be acceptable to the board.

B. Tread end cementing.

1. No owner or other person shall use or permit the use of any tread end cementing process unit unless such unit is equipped with a vapor control system that will remove, destroy or prevent the discharge into the atmosphere of at least 85% by weight of volatile organic compound emissions.

2. Achievement of the emission standard in subsection B 1 of this section by use of methods in 9VAC5-40-610 A will be acceptable to the board.

C. Bead dipping.

1. No owner or other person shall use or permit the use of any bead dipping process unit unless such unit is equipped with a vapor control system that will remove, destroy or prevent the discharge into the atmosphere of at least 85% by weight of volatile organic compound emissions.

2. Achievement of the emission standard in subsection C 1 of this section by use of methods in 9VAC5-40-610 A will be acceptable to the board.

D. Green tire spraying.

1. No owner or other person shall use or permit the use of any green tire spraying operation unless such vapor control methods are applied that will remove, destroy or prevent the discharge into the atmosphere of at least 95% by weight of volatile organic compound emissions.

2. Achievement of the emission standard in subsection D 1 of this section by use of methods in 9VAC5-40-610 B will be acceptable to the board.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0603, eff. July 1, 1991.

9VAC5-40-610. Control technology guidelines.

A. Undertread cementing, tread end cementing and bead dipping. The control system should consist of one of the following:

1. Carbon adsorption system.

2. Incineration system.

3. Any system of equal or greater control efficiency when compared to the standard in 9VAC5-40-600 A 1, B 1, or C 1 as applicable, provided such system is approved by the board.

B. Green tire spraying. The control method should consist of one of the following:

1. Use of water based sprays;

2. Carbon adsorption;

3. Incineration; or

4. Any method of equal or greater control efficiency when compared to the standard in 9VAC5-40-600 D 1, of this section, provided such method is approved by the board.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0604, eff. July 1, 1991.

9VAC5-40-620. Standard for visible emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0605, eff. January 1, 1985.

9VAC5-40-630. Standard for fugitive dust/emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0606, eff. January 1, 1985.

9VAC5-40-640. Standard for odor.

The provisions of Article 2 (9VAC5-40-130 et seq.) of this chapter (Emission Standards for Odor, Rule 4-2) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0607, eff. January 1, 1985.

9VAC5-40-650. Standard for toxic pollutants.

The provisions of Article 3 (9VAC5-40-160 et seq.) of this chapter (Emission Standards for Toxic Pollutants, Rule 4-3) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0608, eff. January 1, 1985.

9VAC5-40-660. Compliance.

The provisions of 9VAC5-40-20 (Compliance) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0609, eff. January 1, 1985.

9VAC5-40-670. Test methods and procedures.

The provisions of 9VAC5-40-30 (Emission Testing) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0610, eff. January 1, 1985.

9VAC5-40-680. Monitoring.

The provisions of 9VAC5-40-40 (Monitoring) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0611, eff. January 1, 1985.

9VAC5-40-690. Notification, records and reporting.

The provisions of 9VAC5-40-50 (Notification, Records and Reporting) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0612, eff. January 1, 1985.

9VAC5-40-700. Registration.

The provisions of 9VAC5-20-160 (Registration) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0613, eff. January 1, 1985.

9VAC5-40-710. Facility and control equipment maintenance or malfunction.

The provisions of 9VAC5-20-180 (Facility and Control Equipment Maintenance or Malfunction) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0614, eff. January 1, 1985.

9VAC5-40-720. Permits.

A permit may be required prior to beginning any of the activities specified below and the provisions of 9VAC5 Chapter 50 (9VAC5-50-10 et seq.) and 9VAC5 Chapter 80 (9VAC5-80-10 et seq.) may apply. Owners contemplating such action should contact the appropriate regional office for guidance.

1. Construction of a facility.

2. Reconstruction (replacement of more than half) of a facility.

3. Modification (any physical change to equipment) of a facility.

4. Relocation of a facility.

5. Reactivation (restart-up) of a facility.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0615, eff. January 1, 1985.

Article 7

Emission Standards for Incinerators (Rule 4-7)

9VAC5-40-730. Applicability and designation of affected facility.

Article 7

Emission Standards for Incinerators (Rule 4-7)

A. The affected facility to which the provisions of this article apply is each incinerator.

B. The provisions of this article apply throughout the Commonwealth of Virginia.

C. The provisions of this article do not apply to facilities that are designed as boilers to produce steam or heated water and are designed to burn either fossil fuel or refuse derived fuel. It does apply to such facilities if designed to burn raw refuse.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0701, eff. January 1, 1985.

9VAC5-40-740. Definitions.

A. For the purpose of these regulations and subsequent amendments or any orders issued by the board, the words or terms shall have the meanings given them in subsection C of this section.

B. As used in this article, all terms not defined here shall have the meanings given them in 9VAC5 Chapter 10 (9VAC5-10-10 et seq.), unless otherwise required by context.

C. Terms defined.

"Incinerator" means any furnace or device used in the process of burning waste for the primary purpose of destroying matter or reducing the volume, or both, of the waste by removing combustible matter.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0702, eff. January 1, 1985.

9VAC5-40-750. Standard for particulate matter.

No owner or other person shall cause or permit to be discharged into the atmosphere from any incinerator any particulate emissions in excess of .14 grains per standard cubic foot of dry flue gas corrected to 12% carbon dioxide (without the contribution of auxiliary fuel).

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0703, eff. January 1, 1985.

9VAC5-40-760. Standard for visible emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0704, eff. January 1, 1985.

9VAC5-40-770. Standard for fugitive dust/emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0705, eff. January 1, 1985.

9VAC5-40-780. Standard for odor.

The provisions of Article 2 (9VAC5-40-130 et seq.) of this chapter (Emission Standards for Odor, Rule 4-2) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0706, eff. January 1, 1985.

9VAC5-40-790. Standard for toxic pollutants.

The provisions of Article 3 (9VAC5-40-160 et seq.) of this chapter (Emission Standards for Toxic Pollutants, Rule 4-3) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0707, eff. January 1, 1985.

9VAC5-40-800. Prohibition of flue-fed incinerators.

Incinerators which use the same flue for feeding the refuse and discharging the gases of combustion are prohibited.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0708, eff. January 1, 1985.

9VAC5-40-810. Compliance.

The provisions of 9VAC5-40-20 (Compliance) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0709, eff. January 1, 1985.

9VAC5-40-820. Test methods and procedures.

The provisions of 9VAC5-40-30 (Emission Testing) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0710, eff. January 1, 1985.

9VAC5-40-830. Monitoring.

The provisions of 9VAC5-40-40 (Monitoring) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0711, eff. January 1, 1985.

9VAC5-40-840. Notification, records and reporting.

The provisions of 9VAC5-40-50 (Notification, Records and Reporting) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0712, eff. January 1, 1985.

9VAC5-40-850. Registration.

The provisions of 9VAC5-20-160 (Registration) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0713, eff. January 1, 1985.

9VAC5-40-860. Facility and control equipment maintenance or malfunction.

The provisions of 9VAC5-20-180 (Facility and Control Equipment Maintenance or Malfunction) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0714, eff. January 1, 1985.

9VAC5-40-870. Permits.

A permit may be required prior to beginning any of the activities specified below and the provisions of 9VAC5 Chapter 50 (9VAC5-50-10 et seq.) and 9VAC5 Chapter 80 (9VAC5-80-10 et seq.) may apply. Owners contemplating such action should contact the appropriate regional office for guidance.

1. Construction of a facility.

2. Reconstruction (replacement of more than half) of a facility.

3. Modification (any physical change to equipment) of a facility.

4. Relocation of a facility.

5. Reactivation (restart-up) of a facility.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0715, eff. January 1, 1985.

Article 8

Emission Standards for Fuel Burning Equipment (Rule 4-8)

9VAC5-40-880. Applicability and designation of affected facility.

Article 8

Emission Standards for Fuel Burning Equipment (Rule 4-8)

A. Except as provided in subsections C, D, and E of this section, the affected facility to which provisions of this article apply is fuel burning equipment.

B. The provisions of this article apply throughout the Commonwealth of Virginia.

C. Exempted from the provisions of this article are the following:

1. Any fuel burning equipment unit using solid fuel with a maximum heat input of less than 350,000 Btu per hour.

2. Any fuel burning equipment unit using liquid fuel (exclusive of coal slurry mixtures) with a maximum input of less than 1,000,000 Btu per hour.

3. Any fuel burning equipment unit using gaseous fuel with a maximum heat input of less than 10,000,000 Btu per hour.

D. The provisions of this article do not apply to fuel burning equipment units that power mobile sources but are removed for maintenance or repair and testing.

E. The provisions of this article do not apply to stationary internal combustion engines.

Statutory Authority

§ 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0801, eff. January 1, 1985; amended, Virginia Register Volume 15, Issue 12, eff. April 1, 1999.

9VAC5-40-890. Definitions.

A. For the purpose of the Regulations for the Control and Abatement of Air Pollution and subsequent amendments or any orders issued by the board, the words or terms shall have the meanings given them in subsection C of this section.

B. As used in this article, all terms not defined here shall have the meanings given them in 9VAC5 Chapter 10 (9VAC5-10-10 et seq.), unless otherwise required by context.

C. Terms defined.

"Capacity factor" means the ratio of the average load on a machine or equipment for the period of time considered to the capacity rating of the machine or equipment.

"Fossil-fuel fired steam generator" means furnace or boiler, or both, used in the process of burning fossil fuel for the primary purpose of providing steam by heat transfer.

"Fuel burning equipment" means any furnace, with fuel burning equipment appurtenances thereto, used in the process of burning fuel for the primary purpose of producing heat to be utilized by indirect heat transfer, or by indirect production of power. This includes facilities that are designed as boilers to produce steam or heated water and are designed to burn either fossil fuel or refuse derived fuel. It does not include such facilities if designed primarily to burn raw refuse. This includes fuel burning equipment units (both permanently installed units and portable units) used to replace the power used by mobile sources. For the purposes of this article, stationary combustion turbines are considered to be fuel burning equipment.

"Fuel burning equipment installation" means all fuel burning equipment units within a stationary source in operation prior to October 5, 1979.

"Heat input" means the total gross calorific value of all fuels burned.

"Rated capacity" means the capacity as stipulated in the purchase contract for the condition of 100% load, or such other capacities as mutually agreed to by the board and owner using good engineering judgment.

"Refuse derived fuel (RDF)" means fuel produced from solid or liquid waste (includes materials customarily referred to as refuse and other discarded materials), or both, which has been segregated and classified, with the useable portions being put through a size reduction and classification process which results in a relatively homogeneous mixture.

"Stationary combustion turbine" means any air-breathing internal combustion engine consisting of an air compressor, combustion chamber, and a turbine wheel.

"Stationary internal combustion engine" means an engine in which fuel is burned within a machine in which energy is converted directly into mechanical motion or work. The energy is used directly for the production of power, locomotion or work. Internal combustion engines include, but are not limited to, diesel engines, gasoline engines, and diesel pumps. For the purposes of this article, stationary combustion turbines are not considered to be stationary internal combustion engines.

"Total capacity" means with reference to a fuel burning equipment installation, the sum of the rated capacities (expressed as heat input) of all units of the installation which must be operated simultaneously under conditions of 100% use load.

Statutory Authority

§ 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0802, eff. January 1, 1985; amended, Virginia Register Volume 15, Issue 12, eff. April 1, 1999; Volume 18, Issue 4, eff. January 1, 2002.

9VAC5-40-900. Standard for particulate matter.

A. Fuel burning equipment installations.

No owner or other person shall cause or permit to be discharged into the atmosphere from any fuel burning equipment installation any gaseous products of combustion containing particulate emissions in excess of the following limits.

1. In AQCR 1 through 6.

a. For fuel burning equipment installations with total capacity less than 10 million (10 X 106) Btu per hour, the maximum allowable emission ratio shall be 0.6 pounds of particulate per million Btu input.

b. For fuel burning equipment installations with total capacity between 10 million (10 X 106) and 10 billion (10,000 X 106) Btu per hour, the maximum allowable emission ration, E, in pounds of particulate per million Btu input, shall be determined by the following equation: E = 1.0906H-0.2594, where H is the total capacity in millions of Btu per hour.

c. For fuel burning equipment installations with total capacity in excess of 10 billion (10,000 X 106) Btu per hour, the maximum allowable emission ratio shall be 0.1 pounds of particulate per million Btu input.

2. In AQCR 7.

a. For fuel burning equipment installations with total capacity less than 100 million (100 X 106) Btu per hour, the maximum allowable emission ratio shall be 0.3 pounds of particulate per million Btu input.

b. For fuel burning equipment installations with total capacity between 100 million (100 X 106) and 10 billion (10,000 X 106) Btu per hour, the maximum allowable emission ratio, E, in pounds of particulate per million Btu input, shall be determined by the following equation: E = .9000H-0.2386, where H is the total capacity in millions of Btu per hour.

c. For fuel burning equipment installations with total capacity in excess of 10 billion (10,000 X 106) Btu per hour, the maximum allowable emission ratio shall be 0.1 pounds of particulate per million Btu input.

B. Fuel burning equipment units.

1. The maximum allowable particulate emissions for each fuel burning equipment unit shall be the product of the rated capacity and the emission ratio (determined in accordance with subsection A of this section).

2. The allowable particulate emissions for each fuel burning equipment unit when operating at less than rated capacity shall be the product of the emission ratio, actual heat input and efficiency factor for the collection equipment. The efficiency factor for the collection equipment of each unit shall be determined using procedures set forth in 9VAC5-40-920.

3. For fuel burning equipment installations consisting of multiple fuel burning equipment units, except where all of the units burn liquid or gaseous fuels, or both, exclusively, the maximum allowable particulate emissions for each unit may be determined as provided in 9VAC5-40-910.

Statutory Authority

§ 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0803, eff. January 1, 1985; amended, Virginia Register Volume 15, Issue 12, eff. April 1, 1999.

9VAC5-40-910. Emission allocation system.

A. This section applies only to fuel burning equipment installations consisting of multiple fuel burning equipment units which do not burn liquid or gaseous fuels, or both, exclusively.

B. The maximum allowable particulate emissions for a fuel burning equipment installation shall be the product of the total capacity and the emission ratio (determined in accordance with 9VAC5-40-900 A).

C. The allowable particulate emissions for a fuel burning equipment installation when operating at less than total capacity, shall be the product of the percent load, emission allocation and efficiency factor for the collection equipment. The percent load shall be the quotient of the actual load and the rated capacity. The efficiency factor for the collection equipment of each unit shall be determined using procedures set forth in 9VAC5-40-920. The emission allocation shall be determined using procedures set forth in subsection D of this section.

D. The emission allocation for each of the fuel burning equipment units of the fuel burning equipment installation shall be its designated portion of the maximum allowable particulate emissions from the fuel burning equipment installation when operating at total capacity. The portions shall be proposed by the owner initially and determined in a manner mutually acceptable to the board and the owner. Once accepted by the board, the portions may not be changed without the consent of the board.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0804, eff. January 1, 1985.

9VAC5-40-920. Determination of collection equipment efficiency factor.

The efficiency factor for the collection equipment shall be established as follows:

1. For all collection equipment, except mechanical collectors, the efficiency factor shall be 1.0.

2. For mechanical collectors, the efficiency factor shall be the quotient of the design efficiency of the collector at rated capacity and the actual efficiency of the collector at the reduced actual load. The actual efficiency shall be the product of the design efficiency and the correction factor where:

|

| Correction Factor = | 1 + log10 (actual load) |

|

| 1 + log10 (rated capacity) |

3. For collection equipment where the owner does not wish to accept the efficiency factor established by subdivision 1 or 2 of this section, the owner may provide information and data as a substitute. Such information and data may be emissions test results or other conclusive evidence. If such information and data is found acceptable by the board, it may be used to establish the efficiency factor for the collection equipment.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0805, eff. January 1, 1985.

9VAC5-40-930. Standard for sulfur dioxide.

A. No owner or other person shall cause or permit to be discharged into the atmosphere from any fuel burning equipment installation any sulfur dioxide emissions in excess of the following limits:

1. S = 2.64K (AQCR 1 through 6).

2. S = 1.06K (for liquid or gaseous fuels - AQCR 7).

3. S = 1.52K (for solid fuels - AQCR 7).

where:

S = allowable emission of sulfur dioxide expressed in pounds per hour.

K = heat input at total capacity expressed in Btu X 106 per hour.

B. Where there is one or more units in a fuel burning equipment installation and where the installation can be shown, to the satisfaction of the board, to be in compliance when the installation is operating at total capacity, the installation will be deemed to still be in compliance when the installation is operated at reduced load or one or more units are shut down for maintenance or repair, provided that the same type of fuel with the same sulfur content, or an equivalent, is continued in use.

C. For installations in AQCR 7 at which different fossil fuels are burned simultaneously, whether in the same or different units, the allowable emissions shall be determined by proration using the following formula:

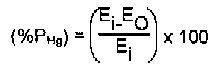

where

PS = prorated allowable emissions of sulfur dioxide expressed in pounds per hour.

X = percentage of heat input at total capacity derived from liquid or gaseous fuel.

Y = percentage of heat input at total capacity derived from solid fuels.

K = heat input at total capacity expressed in Btu x 106 per hour.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0806, eff. January 1, 1985.

9VAC5-40-940. Standard for visible emissions.

A. The provisions of Article 1 (9VAC5-40-60 et seq.) of this part (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply except that the provisions in subsection B of this section apply instead of 9VAC5-40-80 A.

B. No owner or other person shall cause or permit to be discharged into the atmosphere from any fuel burning equipment unit any visible emissions which exhibit greater than 20% opacity, except for one, six-minute period in any one hour of not more than 60% opacity. Failure to meet the requirements of this section because of the presence of water vapor shall not be a violation of this section.

Statutory Authority

§ 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0807, eff. January 1, 1985; amended, Virginia Register Volume 15, Issue 12, eff. April 1, 1999.

9VAC5-40-950. Standard for fugitive dust/emissions.

The provisions of Article 1 (9VAC5-40-60 et seq.) of this chapter (Emission Standards for Visible Emissions and Fugitive Dust/Emissions, Rule 4-1) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0808, eff. January 1, 1985.

9VAC5-40-960. Standard for odor.

The provisions of Article 2 (9VAC5-40-130 et seq.) of this chapter (Emission Standards for Odor, Rule 4-2) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0809, eff. January 1, 1985.

9VAC5-40-970. Standard for toxic pollutants.

The provisions of Article 3 (9VAC5-40-160 et seq.) of this chapter (Emission Standards for Toxic Pollutants, Rule 4-3) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0810, eff. January 1, 1985.

9VAC5-40-980. Compliance.

The provisions of 9VAC5-40-20 (Compliance) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0811, eff. January 1, 1985.

9VAC5-40-990. Test methods and procedures.

The provisions of 9VAC5-40-30 (Emission Testing) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0812, eff. January 1, 1985.

9VAC5-40-1000. Monitoring.

A. The provisions of 9VAC5-40-40 (Monitoring) apply.

B. Unless otherwise approved by the board, owners of fossil-fuel fired steam generators specified in subsection C of this section shall install, calibrate, maintain and operate systems for continuously monitoring and recording specified emissions in accordance with 9VAC5-40-40 and 9VAC5-40-41.

C. Fossil-fuel fired steam generators of greater than 250 million Btu per hour maximum heat input with an annual average capacity factor of greater than 30% (as reported to the Federal Power Commission for calendar year 1974, or as otherwise demonstrated to the board by the owner) shall be monitored for opacity except where:

1. Gaseous fuel is the only fuel burned, or

2. Oil or a mixture of gas and oil are the only fuels burned and the facility is able to comply with applicable particulate matter and visible emission standards without utilization of particulate matter collection equipment, and where the facility has never been found, through any administrative or judicial proceedings, to be in violation of any visible emission standard.

D. The continuous monitoring system shall be spanned at 80, 90 or 100% opacity.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0813, eff. January 1, 1985.

9VAC5-40-1010. Notification, records and reporting.

A. The provisions of 9VAC5-40-50 (Notification, Records and Reporting) apply.

B. For the purpose of reports required under 9VAC5-40-50 C periods of excess emissions that shall be reported are defined as any one-hour period during which there are two or more six-minute periods when the average opacity exceeds 20%.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0814, eff. January 1, 1985.

9VAC5-40-1020. Registration.

The provisions of 9VAC5-20-160 (Registration) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0815, eff. January 1, 1985.

9VAC5-40-1030. Facility and control equipment maintenance or malfunction.

The provisions of 9VAC5-20-180 (Facility and Control Equipment Maintenance or Malfunction) apply.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0816, eff. January 1, 1985.

9VAC5-40-1040. Permits.

A permit may be required prior to beginning any of the activities specified below if the provisions of 9VAC5 Chapter 50 (9VAC5-50-10 et seq.) and 9VAC5 Chapter 80 (9VAC5-80-10 et seq.) apply. Owners contemplating such action should review those provisions and contact the appropriate regional office for guidance on whether those provisions apply.

1. Construction of a facility.

2. Reconstruction (replacement of more than half) of a facility.

3. Modification (any physical change to equipment) of a facility.

4. Relocation of a facility.

5. Reactivation (restart-up) of a facility.

6. Operation of a facility.

Statutory Authority

§ 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0817, eff. January 1, 1985; amended, Virginia Register Volume 15, Issue 12, eff. April 1, 1999.

Article 9

Emission Standards for Coke Ovens (Rule 4-9)

9VAC5-40-1050. Applicability and designation of affected facility.

Article 9

Emission Standards for Coke Ovens (Rule 4-9)

A. The affected facilities in coke plants to which the provisions of this article apply are: horizontal slot sole-flue nonrecovery ovens and horizontal slot nonrecovery ovens.

B. The provisions of this article apply throughout the Commonwealth of Virginia.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0901, eff. January 1, 1985.

9VAC5-40-1060. Definitions.

A. For the purpose of these regulations and subsequent amendments or any orders issued by the board, the words or terms shall have the meanings given them in subsection C of this section.

B. As used in this article, all terms not defined here shall have the meanings given them in 9VAC5 Chapter 10 (9VAC5-10-10 et seq.), unless otherwise required by context.

C. Terms defined.

"Charging" means the process by which coal is introduced into a coke oven beginning when coal enters the oven and ending when the door is closed.

"Coking" means the process by which coal is converted to coke by means of destructive distillation using heat.

"Pushing" means the process by which coke is removed from a coke oven, including the period marked by the time when the doors are first removed from a coke oven until quench water is applied to the hot coke.

"Quenching" means the process by which the combustion of hot coke is stopped by application of water or any other procedure achieving the same affect.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0902, eff. January 1, 1985.

9VAC5-40-1070. Standard for particulate matter.

A. No owner or other person shall cause or permit to be discharged into the atmosphere from any horizontal slot sole-flue nonrecovery oven any particulate emissions from coking, charging and pushing operations in excess of a combined total of 0.15 pounds of particulate/hour/ton of coal, as charged.

B. No owner or other person shall cause or permit to be discharged into the atmosphere from any horizontal slot nonrecovery oven any particulate emissions from coking, charging and pushing operations in excess of a combined total of 0.13 pounds of particulate/hour/ton of coal, as charged.

C. No owner or other person shall cause or permit to be discharged into the atmosphere from any affected facility during the quenching operation any particulate emissions in excess of that resultant from use of a quench tower incorporating state-of-the-art engineering design.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0903, eff. January 1, 1985.

9VAC5-40-1080. Standard for sulfur dioxide.

No owner or other person shall cause or permit to be discharged into the atmosphere from any affected facility any sulfur dioxide emissions in excess of the following limit:

S = 2.64K

where:

S = allowable emission of sulfur dioxide expressed in pounds per hour.

K = actual heat input expressed in Btu X 106 per hour.

Statutory Authority

§§ 10.1-1307 and 10.1-1308 of the Code of Virginia.

Historical Notes

Derived from VR120-04-0904, eff. January 1, 1985.

9VAC5-40-1090. Standard for visible emissions.